The aggregate sector holds critical importance in the production of high-quality construction materials. Numerous tests are conducted to determine the physical, chemical, and mechanical properties of aggregates. These tests are carried out to ensure the durability and performance of the material when used in the construction sector. Let’s take a closer look at the details of aggregate tests together.

Contents

1. Aggregate Sampling Methods

To accurately analyze the properties of aggregates, proper sampling techniques must be used first. The most common methods are:

• Quartering Method: In this method, the aggregate sample is quartered homogeneously to achieve the appropriate analysis size.

• Using a Sample Splitter: With the help of sample splitters, the aggregate sample is divided into equal parts, and the necessary amount for analysis is obtained.

2. Determination of Physical Properties

The physical properties of aggregates play a critical role in determining the strength and longevity of the material. The following two tests are among the most frequently applied:

2.1 Moisture Condition of Aggregate: The moisture content of the aggregate is crucial for determining the correct water/binder ratio before use in fresh concrete mixtures.

2.2 Sieve Analysis: Sieve analysis reveals the granulometric structure of the aggregate and determines the amount of each particle size present. This test helps optimize aggregate gradation.

3. Determination of Mechanical Properties

The mechanical strength of aggregates is important for meeting the longevity and durability requirements of most structures.

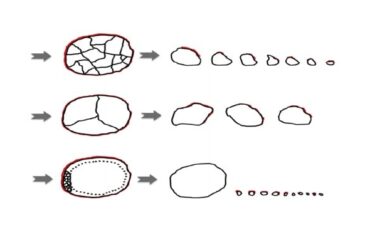

3.1 Particle Strength: This test measures the resistance of aggregates to fragmentation under severe loads.

3.2 Abrasion Resistance Test (Los Angeles Test): Conducted using the Los Angeles drum, this test determines the abrasion characteristics of aggregates and evaluates their durability.

3.3 Freeze-Thaw Resistance: This test measures the resistance of aggregates to freeze-thaw cycles.

4. Determination of Harmful Substances

Harmful substances contained in aggregates used in concrete and other construction materials can negatively affect structural performance.

4.1 Alkali-Silica Reaction: This test evaluates the potential of aggregates to react with alkali-containing cement, which could damage the structure.

5. Screen Analysis and Gradation

Screen analysis is one of the most important tests for determining aggregate gradation. This test accurately determines the size distribution of aggregates, optimizing the necessary properties before use. ASTM and ISO standards specify special requirements for the sieves used in these analyses.

Aggregate tests are critical for producing high-quality and durable construction materials in the industry. At Uğur Makina, we develop sector-specific solutions and provide our customers with the most suitable equipment and technical support. You can contact us for more detailed information.