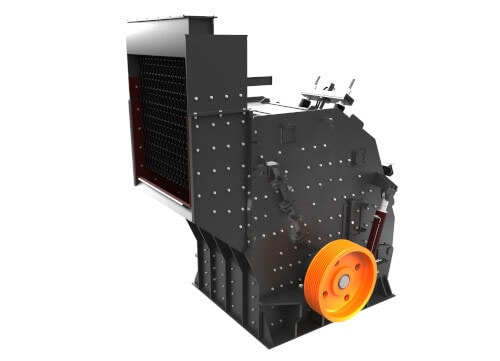

UĞURMAK CDK Series Primary Impact Crushers have a design that allows the rotor, two pendulum systems and wear plates to work in harmony. Thanks to this compatibility, it offers high performance and low operating costs. It can provide very high size reduction ratios in breaking not very hard and non-abrasive materials. Thanks to these advantages, they are preferred in primary crushing stage in crushing and screening plants. According to the design of the facility, they can be manufactured as mobile, with fixed steel legs, with fixed concrete legs, with fixed skid chassis.

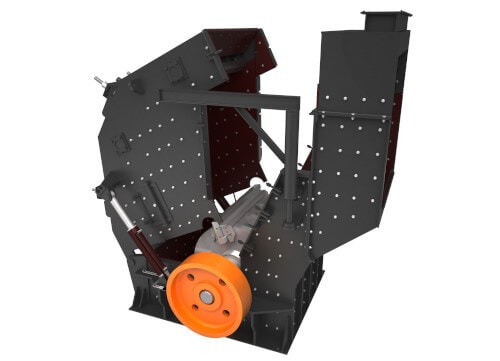

CDK consists of three main parts. Rotor, fixed lower body and opening top body. The upper body rotates around a hinge fixed to the lower body with the help of the hydraulic mechanism enough to expose the rotor and the internal parts..

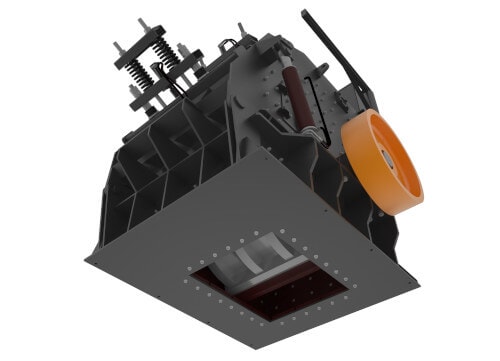

The lower body is fixed to the carrier frame. It’s main task is to carry the rotor. In addition, the upper body, inlet groove and maintenance crane mechanism are mounted on the lower body.

There are two pendulum systems on the upper body to adjust the product curve and adjustment mechanisms connected to these pendulums. Also, the rotor side is covered with crushing plates.

The taps are designed to narrow the distances to the rotor, respectively. This allows to perform a two-step crushing process. It is fixed to the body from the upper edges by a fixed hinge, and the lower edges are held by adjustment studs.

As a result of the movement given to the rotor, a high amount of kinetic energy is generated in the pallets. Very strong blows are applied to the material fed to the machine with this energy. As a result of the impact, the crushing process is carried out by hitting the material against the crushing plates. The material is shrunk enough to pass through the narrowest distance between the crushing plates and rotor pallets connected to the first pendulum system. In this way, the material, which is shrunk from the first stage to a certain size, can go to the second stage. Here, similar processes are repeated and the product obtained passes into the discharge chute..

Pendulum

There are upper and lower pandula system independent from each other. It takes part in the first stage of the upper pandulum breaking process and the second stage of the lower pandulum. It provides a more reliable and long-lasting crushing system thanks to its squeeze safety system. The pendulum opening can be adjusted easily and safely with the help of hydraulic cylinders according to the product curve expected from the machine.

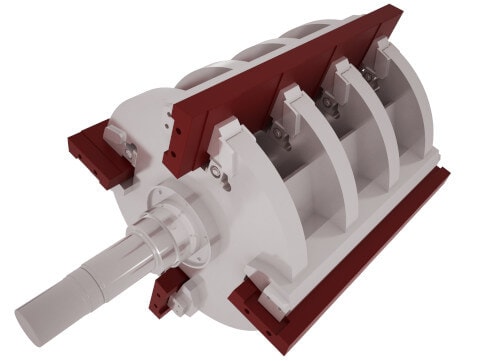

Palette

Reverse-Flat can be used. It shows high resistance to breakage. It is self-centered and assembled. It is firmly mounted on the rotor body with special wedges. It is fixed with pallet holders against lateral movements. In this way, it maintains its place in all cases.

Linings

They are manufactured from manganese alloy steel castings with high abrasion resistance. They are produced in pieces for easy replacement and are attached to the body with bolts.

Rotor

It is manufactured as steel casting. Heat treatment is applied. The parts that may be exposed to wear are reinforced with hard filling welding. There is a ductless flywheel on the opposite side of the machine pulley, which works idler and balances the load distribution. With this idler flywheel, the pulley of the belt can be replaced by replacing the pulley of the machine if needed.

Body

The crusher body with welded design provides long life thanks to its high strength. It has two main structures named as lower body and upper body. Of these, the lower body is fixed and the upper body can be opened and closed. Opening and closing is done with hydraulic cylinders. In addition, thanks to the sight caps on both sides of the body, both the adjustment process is controlled and the condition of the wear parts can be checked quickly.

- High Capacity and Performance

- The large feeding nozzle, high-strength crushing plates and the strong rotor allow a large size feed for high capacity production. It is done at the maximum level and provides high efficiency in all working conditions. The most important result of this efficiency is low operating costs and energy savings.

- CDK Series crushers provide a much higher size reduction ratio with 2-stage crushing process.

Easy and Safe Maintenance

- The upper body can be opened easily with the hydraulic power unit and hydraulic cylinders located on both sides of the body. Liner changes, pallet changes can be made easily by this way.

Quick and Easy Installation