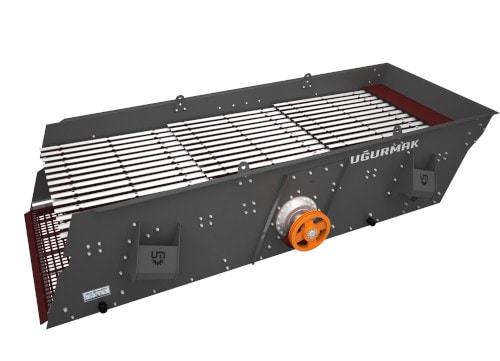

UĞURMAK UMIE series Grizzly Screens are generally used in two different stages of crushing and screening process.

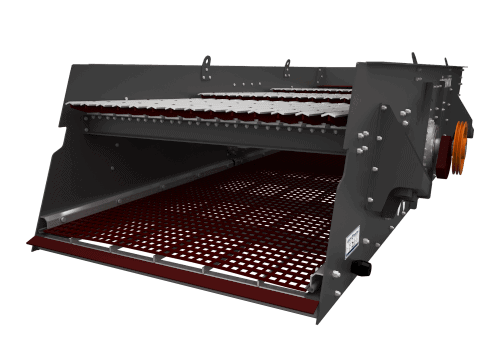

- It is placed between the feeder and the primary crusher. It is used to separate the product that will go to the primary crusher from the feeder and be bypassed.

- It is put in front of the secondary crusher. Bypassing the small material coming from the primary crusher, it ensures that it does not enter the secondary crusher.

The reason why it is preferred at these stages is that the material to be fed to this screen consists of very large material. Standard screens can not meet the desired capacity and due to the size of the material, the standard steel mesh may need to be replaced in a short time.

Grizzly vibrating screens are manufactured in two decks in various sizes and capacities. Grizzly spaces can be easily adjusted according to the material size to be bypassed.

Vibration is obtained by rotating the eccentric weights connected to the shaft mounted on the screen body, as in the other screens. The drive system is designed in such a way that the vibration required by the effective screening can be easily adjusted with the adjustable weight system.