The most preferred reason for UĞURMAK brand mobile crushing units is the ease of assembly and disassembly. Temporary project works such as dams, road construction may need to be moved to a different site at the end of the project. In such cases, as these plants offer ease of transportation, they significantly reduce transportation costs.

Taking these advantages into consideration, UĞURMAK has developed the mobile primary unit with UMK jaw crusher in order to be used in primary stage.

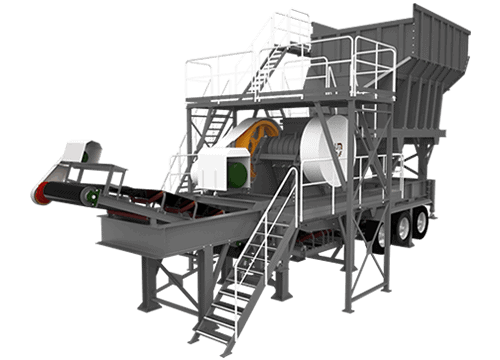

On the unit, there is a grizzly feeder and bunker, UMK series primary jaw crusher. Mobile unit design is available for UMK90, UMK110, UMK120 and UMK130 models.

With the help of one truck, transport provided. In order to facilitate the mounting of the feet during the installation, the chassis is raised thanks to the hydraulic feet on it and the steel feet are mounted and fixed on the ground.