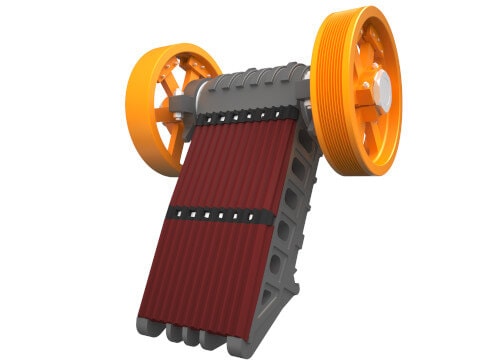

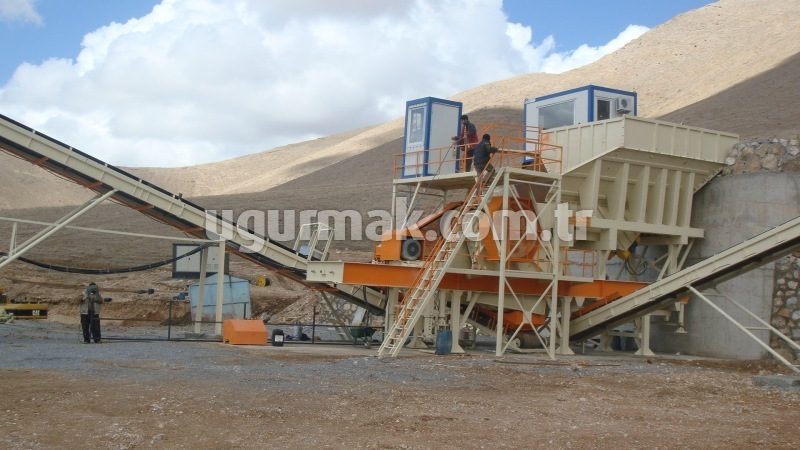

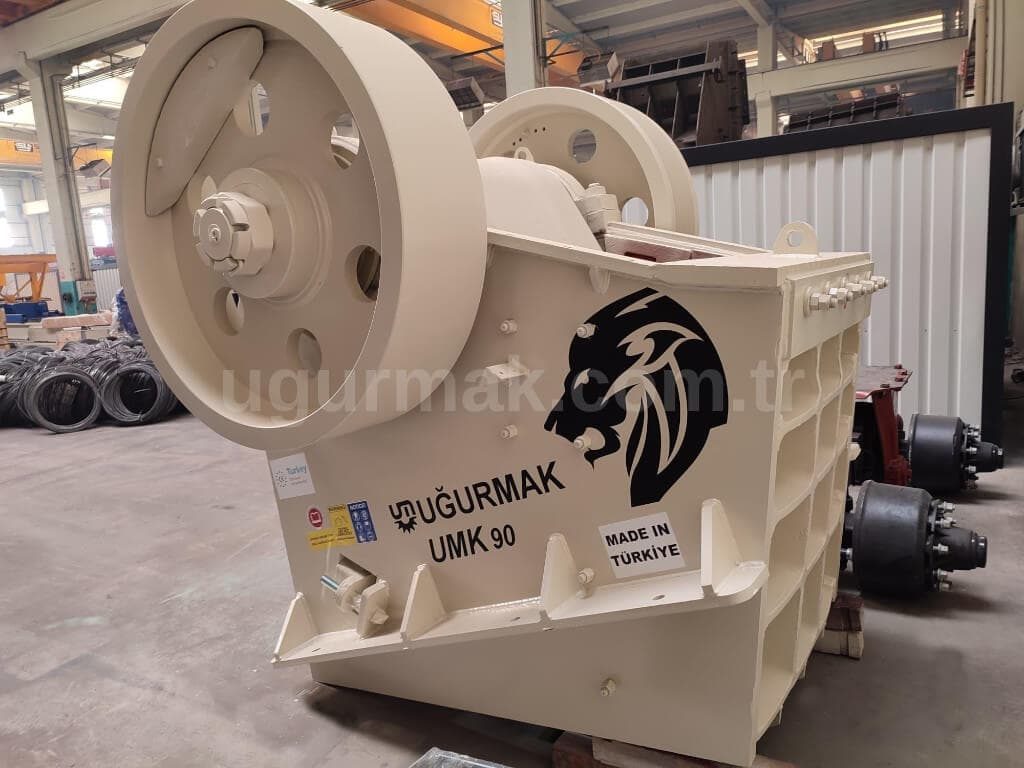

UGURMAK UMK Series Jaw Crushers are the most preferred types of crushers due to their strong design, ability to crush materials of any hardness, low operating costs and easy maintenance. Depending on the location of the facility, they can be manufactured as mobile, fixed steel legs, fixed concrete legs, and fixed skid chassis.

Although jaw crushers are generally used in the Primary stage, secondary types are preferred for secondary crushing also.

Crushing of Jaw crushers is provided by applying a high amount of pressure to the material fed. This mechanical pressure is provided by the elliptical movement of the movable jaw and the narrowing angle between the fixed jaw. The fed material is gripped by this elliptical movement and compressed between the fixed jaw and the movable jaw. The high flywheel speed, the optimal jaw gripping angle and the specially designed geometry between the pitman and the back block ensure that this mechanical pressure is applied to the maximum level in a controlled manner. Therefore, UMK Series Jaw Crushers have the strongest breaking circle that offers superior success in all working conditions.

Jaw Opening Adjustment

The jaw opening is adjusted according to the product curve desired by the machine, by adding or decreasing shim plates to the back of the adjustment block. The adjustment time is very short and easy, as this setting is supported by the hydraulic system.

Jaws

Fixed and mobile jaws are made of manganese steel casting and their back surfaces are processed so that they do not damage the surfaces they lean on and are more resistant to breakage due to any possible itching.

Shaft

Crusher shafts are manufactured from forged steel by precision machining. The eccentricity of the shaft provides the elliptical movement of the movable jaw. Bearings are with spherical roller bearings. Bearings are grease lubricated. It is protected by labyrinth system against external influences

Safety Plate

It is manufactured from cast iron. During the material feed, it ensures the safety of the drive system against the risk of unintentional iron parts. It is designed in geometry that can break under overload. It breaks down, allowing the iron piece to move away from the machine.

Body

It provides long life thanks to its high strength structure. It has a welded design. After welding, heat treatment is applied for stress relief.

High performance and Strength

Due to the shape of crushing, it shows very little wear in abrasive mines compared to impact crushers

Long Life Against Wear

It is long lasting thanks to its durable body structure.

Long operation period with Low Maintenance

It does not require daily maintenance except lubrication.

High Efficiency in Large Dimensions

It enables processing of raw material in larger sizes compared to impact crushers.

Easy Setting

The adjustment time is reduced to minimum with the hydraulic system.

Low Operating Cost

Low energy consumption. High capacity operation at low kW.