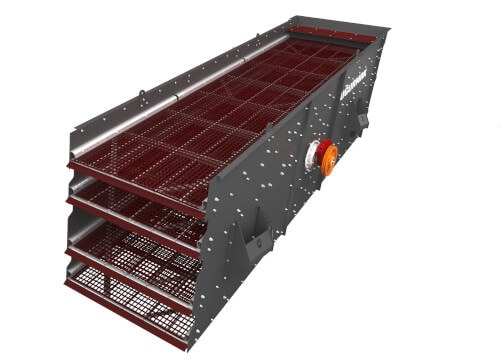

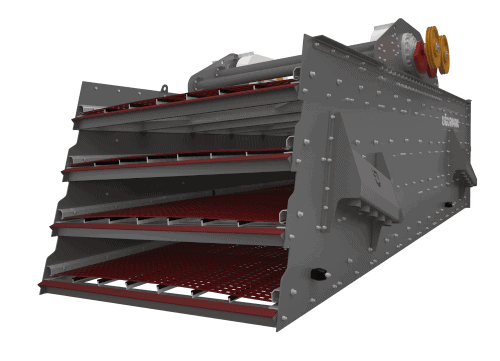

UĞURMAK UME series Inclined Screens provide separation of crushed material. It can be used in all the stages of a crushing and screening process, where it is necessary to classify the products by size. The main task is to receive the end product. Therefore, the screen determines the actual capacity of the process. UME series inclined screens have a more reliable body structure against the negative effects of vibration movement with its unique body design.

When the material is poured into the screen, it moves forward on the screen mesh with a certain speed by vibration and is laid homogeneously on the screen. At this stage, the material smaller than the screen size passes to the lower floor.

Body

Vibrating screens are manufactured in two, three and four decks in various sizes and capacities.

Screening Mechanism

The design makes it possible for use of several screen meshes such as perforated sheet, perforated hardox sheet, polyurethane and the most preferred steel mesh.

Screen meshes are the most replaced part as the abrasion of the screened material. Because of this all our mesh holders are designed as rails for ease of assembly and disassembly. Necessary maintenance and changes can be easily made by pushing the front cover during mesh change. In addition, the screen decks are wide in terms of ease of screen mesh.

Drive System

The drive system is manufactured as a single or double drive in the middle or above the screen body. The vibration is obtained by rotating the eccentric weights attached to the bearing shaft in the screen body. By changing the position of these eccentric weights relative to each other, the vibration amplitude of the screen can be easily adjusted. In this way, the UME series vibrating screen is easily brought to the optimum setting for high performance.

Elastic System

The screen body sits on the chassis with heavy type helical springs that provide vibration. Chassis and chutes are not affected by vibration occurring in the screen body.

Washing System

According to the desired product features in the crushing and screening process, there may be a need for a washing system on the vibrating screen. In this case, screen in desired size can be equipped with suitable washing system.

There are nozzles lined up across the screen. These nozzles spray the water in a way that creates a water curtain on the screen wire. The material advancing on the screen mesh, while passing through this water curtain, dissolves the unwanted particles adhered to it and allows it to pass under the screen together with the water.

High Capacity and Efficiency

The material poured into the feed chute speeds up to the front, which ensures a homogeneous distribution of the material density on the screen. At this stage, the fine material is easily sieved. Thus, it works with high capacity and efficiency.

Easy and Safe Maintenance

The front chute has a rail system, and the mesh can be replaced easily and quickly. Having service platform on four sides of the screen body provides safe and easy maintenance.

Quick and Easy Installation