Stone crushing and screening plants, a key sub-sector of the mining industry, have long been associated with high capital investments, heavy industrial machinery, and manual operations. However, with the acceleration of digitalization in recent years, this traditional structure has begun to show signs of transformation. The rapid development of artificial intelligence (AI) technologies, in particular, is bringing a new vision to the sector in both production and management.

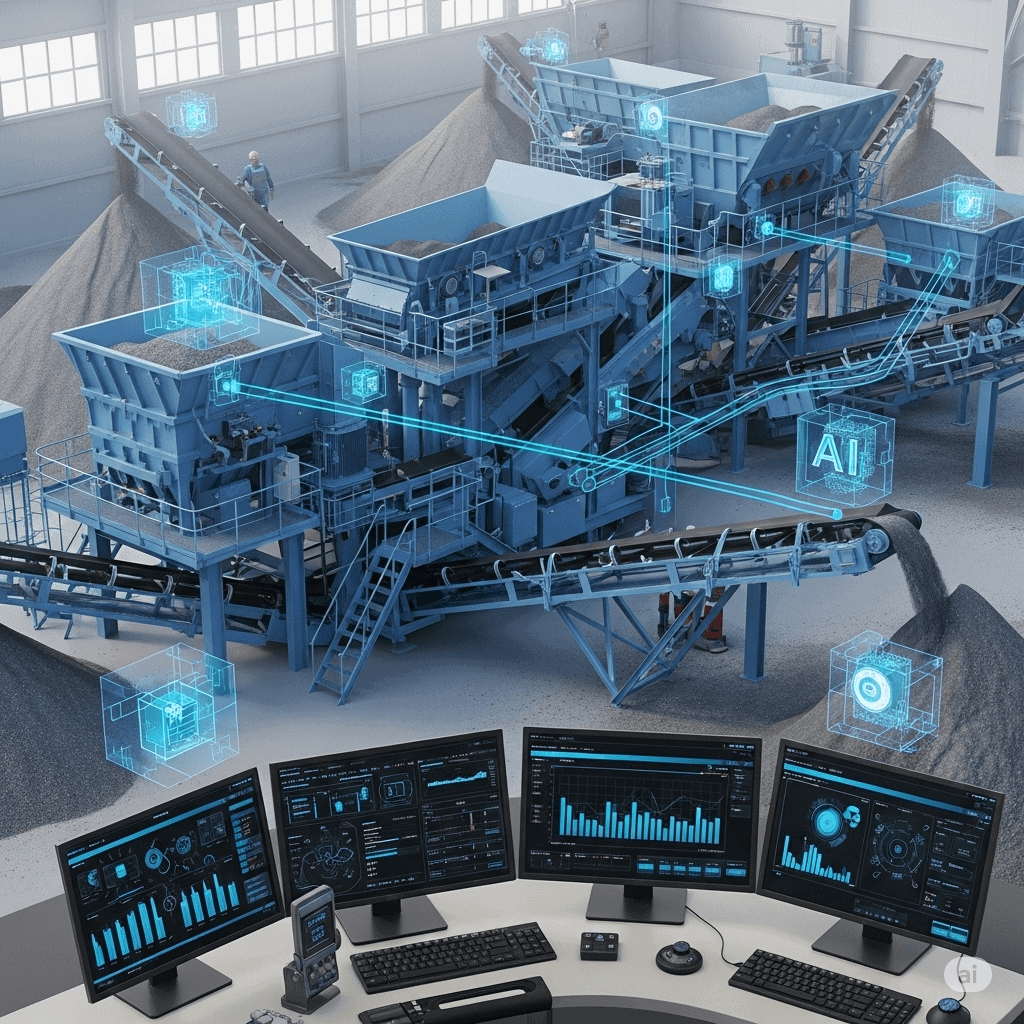

Today, all processes, from crushers to screening systems, from conveyor belts to crushers, are becoming smarter, more efficient, and more scalable thanks to data-driven algorithms. Artificial intelligence applications are not limited to production optimization; they also directly contribute to areas such as maintenance management, cost analysis, sales forecasting, inventory planning, occupational safety, and sustainability.

This transformation brings new opportunities that will provide a competitive advantage not only for large-scale manufacturers but also for medium and small-scale facilities. With the right applications, artificial intelligence can reduce production costs while improving quality, reduce human error, accelerate sales processes, and increase efficiency. Here, we attempted to address the potential transformation that artificial intelligence will bring to stone crushing and screening plants from various perspectives. As Uğur Makina, we are aware of all these developments and are aware of the need to revise our future projections accordingly.

1. Process Automation and Parameter Optimization

• Settings (e.g., speed, inclination, vibration frequency) for equipment such as crushers, screens, and feeders can be optimized in real time using Artificial Intelligence (AI).

• The most suitable crushing and screening plans/drawings are automatically determined by the system based on the material type.

• Human intervention is reduced, and processes and workflows are continuously programmed to operate under ideal conditions.

2. Quality Control and Automatic Classification with Image Processing

• Camera and sensor systems enable instant aggregate size analysis on exit conveyors.

• Quality parameters such as color, dirt content, and deformity are automatically classified using Artificial Intelligence (AI).

• Non-conforming materials are separated from the system, maintaining quality standards.

3. Predictive and Predictive Maintenance

• Vibration, temperature, noise, and torque data are analyzed to predict malfunctions before they occur.

• Spare parts inventories are intelligently managed, and maintenance schedules are planned.

• Unplanned downtime and equipment failures are minimized.

4. Energy and Fuel Efficiency

• Artificial Intelligence (AI) analyzes machinery’s energy consumption profiles and optimizes energy-consuming processes.

• In generator-powered mobile facilities, fuel consumption is monitored in real time, resulting in savings.

• Carbon footprint is reduced while energy costs are controlled.

5. Autonomous and Remotely Controlled Operations

• Remote monitoring and control systems reduce the need for operators. Potential employee-related problems are minimized.

• Autonomous robotic crushers ensure occupational safety, especially in hazardous areas. Employee health is prioritized.

• Multiple facilities can be managed from a central control room. Administrative aspects are simplified in large-scale operations.

6. Demand Forecasting, Inventory Management, and Production Planning

• Production forecasts are created by analyzing information such as customer demands, construction site data, and weather conditions.

• Production planning becomes dynamic; data-based determination of what to produce and when is achieved is achieved.

• Inventory is balanced, reducing the risk of overproduction or undersupply.

7. Dynamic Pricing and Automated Quotation Systems

• Cost data, market prices, and customer segments are analyzed to provide AI-supported price suggestions.

• Quotation systems are automated, reducing quotation time.

• Sales teams can focus on more strategic areas, and the workload of the quotation unit is reduced. 8. Sustainability Analytics for Emission, Noise, and Dust Control

• Dust level, sound level, and emission data are monitored with sensors and analyzed using Artificial Intelligence (AI).

• Automatic environmental reports can be generated for regulatory compliance. This avoids potential red tape with both internal companies and public institutions.

• Systems that consume unnecessary water, fuel, or energy are instantly alerted or disabled.

8. Training, Simulation, and Operator Performance Monitoring

• Virtual reality-supported training simulations accelerate the learning process for operators. Cost-effective solutions are developed for companies.

• Operators’ impact on processes is observed, and Artificial Intelligence (AI) identifies energy consumption or setting errors.

• Performance-focused training plans are developed, and the right person is assigned to the right job.

9. Market Analysis, Competitor Tracking, and Strategic Decision Support Systems

• Artificial Intelligence (AI) provides competitive advantage by analyzing competitors’ digital footprints (prices, campaigns, customer reviews). • It offers data-based answers to questions such as which region should be entered with which product and when to invest in new facilities.

• Management decisions can no longer be made intuitively, but through AI-powered analysis.

Artificial intelligence (AI) has the potential to make the stone crushing and screening industry not only “more digital” but also more competitive, more efficient, and more environmentally friendly. However, the first step towards this transformation is collecting data with sensors, digitally monitoring machines, and establishing the software infrastructure that can interpret this data.

Companies that take the right steps will not only build today’s mining industry, but also the future of mining. At Uğur Makina, we monitor the sector globally and continue to do everything we can to ensure that both we and our stakeholders keep pace with developments. We are aware that not only technical equipment and machinery but also skilled workforce are crucial for this.