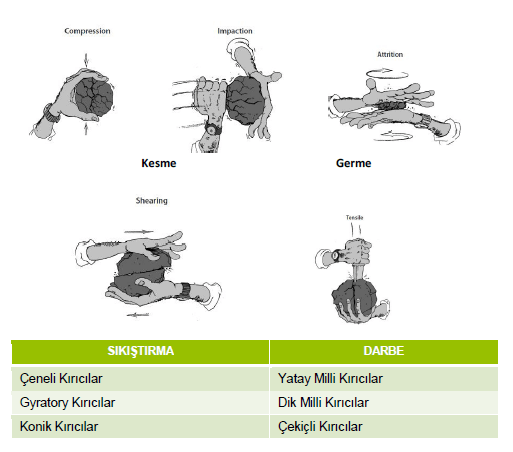

Basic Crushing Principles in Crushing and Screening Plant The ore extracted by mining should be reduced in size according to the area of use. The process of breaking the raw material extracted from the mastra into small pieces of different sizes is called crushing. In order for the crushing to take place, a force in the form of impact, shear, pressure or shearing to be applied to the raw material from the outside is applied to reduce its size. Equipment with mechanical power to provide this reduction is called crusher or crusher. Crushing by impact method occurs when the rock moving at high speed hits a fixed machine element. It is provided with horizontal shaft crushers, vertical shaft crushers and hammer crushers. Crushing by compression method takes place with the pressure between two surfaces, one fixed and the other movable, and is provided by jaw crushers and cone crushers .

Uğurmak is a leading manufacturer specializing in crushing, screening, and washing plants for the mining, construction, and recycling industries. The company offers a wide range of high-performance machines, including jaw crushers, impact crushers, cone crushers, vibrating screens, and washing systems, designed to process a variety of materials such as rock, ore, and construction waste. Uğurmak’s products are built to meet the demands of heavy-duty applications, providing efficiency, durability, and ease of operation.

Copyright © 2024, All Rights Reserved.