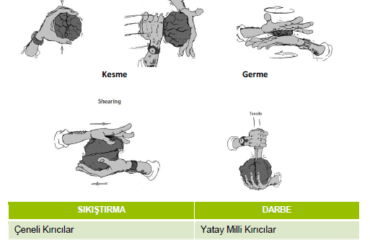

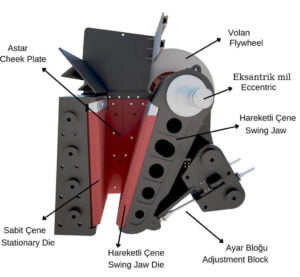

Ugurmak Jaw crusher is a compression-type crusher consisting of a fixed jaw and movable jaw enclosed in a (V). The movable jaw crushes the material to the desired size by compressing it against the fixed jaw. The material exits the jaw from under the crusher, otherwise known as the discharge opening. Changing the discharge opening determines the size of the product made by the crusher. Jaw crushers are mainly used in rock and quarries, sand and gravel, mining, construction and demolition recycling, construction aggregates, the stage of material grinding in various applications. The jaw crusher’s flywheel, knuckle plates, pitman, camshaft and drive motor create the crushing motion and provide the energy needed to crush the material.

There are some different styles of Jaw Crushers, the most common being the overhead eccentric jaw (shown above) or the double-pass jaw. Depending on the application requirements, jaw crushers, fixed jaw crushers, mobile jaw crushers, different situations vary according to location and transportation possibilities. Generally, the dimensions of jaw crushers are determined by the size of the upper opening through which the material enters. Openings tend to be rectangular or square and are indicated in inches. For more information about jaw crushers, you can fill out the contact form or call +90 (312) 267 41 11

There are some different styles of Jaw Crushers, the most common being the overhead eccentric jaw (shown above) or the double-pass jaw. Depending on the application requirements, jaw crushers, fixed jaw crushers, mobile jaw crushers, different situations vary according to location and transportation possibilities. Generally, the dimensions of jaw crushers are determined by the size of the upper opening through which the material enters. Openings tend to be rectangular or square and are indicated in inches. For more information about jaw crushers, you can fill out the contact form or call +90 (312) 267 41 11