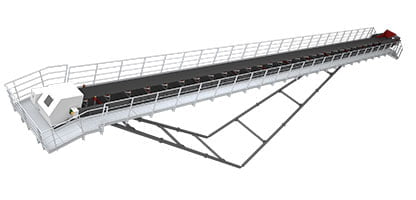

Belt conveyors are particularly successful in transporting bulk materials such as mineral ores, stone, sand and grain at high capacities and over long distances. A belt conveyor consists of an endless belt stretched between two drums. Belt conveyors are usually the most suitable solution when stacking material needs to be transported over long distances without stopping. They are used horizontally or with a low slope. The material to be transported can be sand or granule.

UGURMAK brand UB series belt conveyors have modular design. It provides ease of transportation and assembly. It is the equipment that connects the stages of a crushing and screening process. They take part in transporting the material between the machines and stocking the final products classified according to their size by completing the process.

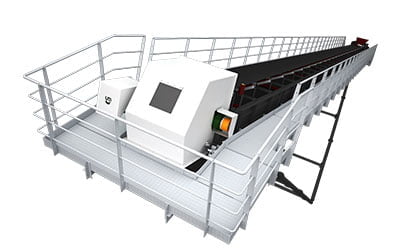

The drum to which the drive system is connected is called the drive drum. The other drum, which usually performs the tensioning task and located at the other end of the belt, is called the tensioner drum or tail drum. The belt on these drums is carried by the carrier and return rollers attached to the frame. To prevent the belt from sliding left or right during this transportation, a direction roller is installed in the side compartments. The material fed to the belt is transported by a rubber band moved by these drums. There is a loading chute to feed the material to the belt and a discharge chute to discharge the material from the belt.

• It can be produced in 600, 800, 1000 and 1200 mm width and desired length. There are two types of tape chassis: NPU chassis or Sigma Twist Sheet Chassis. Selection can be made according to the place of use.

• Bolt tensioning is used for up to 40 m length, weighted tensioner is used on conveyors with 40 meters length and longer.

• Belt conveyors are with walking platforms as one-sided, double-sided or U-platformed, according to the customer demand, in order to follow up the operation and provide ease of maintenance and intervention.

• There is a cleaning device to remove the residues of the material carried from the rubber band.

• Mechanical brake connected to the drive drum is to prevent the material on the belt from sliding back.

• In order to make a sudden stop in emergency situations, there is a pull-cord switch along the walking platform.

• Dust exit is prevented by hinged designed closing that can be opened and closed easily.

• Depending on customer demand, it can be equipped with safety equipment such as belt slide switch, magnet, metal detector and magnetic separator.