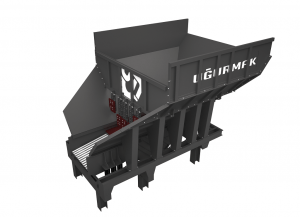

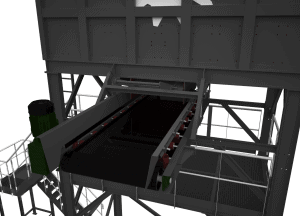

Ugurmak Feeders used in the Crushing and Screening Plant are produced in a way that can be adapted to work with heavy conditions and highly abrasive materials. The feeders are produced with a strength that can withstand the impacts of the stones poured into the chamber and special sheets are used on the sides of the base against wear. Below, we’ve outlined the types of feeders to help you determine which one is right for your application. Vibrating Feeders Primary crushers are called rocks, etc. They are used to feed coarse material. Vibrating feeders have a durable body. They have a durable chamber and chassis that can handle the impact of the raw material emptied into it. The hoppers of the bunkers used on the Vibrating Feeders can range from 10 cubic meters to 100 cubic meters. They are feeders used to feed the material poured into the hopper to the desired place. Vibratory feeders are driven by vibration motors or eccentric-weighted mechanical drive systems with gearboxes. Vibrating feeders should also use vibration-resistant sheets.  Crawler Feeders Crawler Feeder is one of the heavy-duty feeders that can be used in the most difficult conditions for primary crushers, material feeding It is not the first time that I have been able The undercarriage, which is also used in crawler machines, is driven by a low-speed planetary gearbox or a parallel shaft or chuck gearbox. The drive shaft is connected from the double-sided drive gear center. With the rotation of the drive sprocket, it moves the pallet chains and therefore the pallets, and takes the material/ore on the Apron feeder. The pallet is hard to wear because it is cast with high manganese. Therefore, they are used in the most difficult conditions Crawler feeders are feeders used in primary hoppers when the crushed material becomes sticky with the effect of moisture as a result of containing soil or clay. Thanks to its strong structure and pallet system, it prevents feeding problems no matter how dirty and sticky the fed material is. For this reason, it is preferred in high-capacity (400 TPH and above) facilities.

Crawler Feeders Crawler Feeder is one of the heavy-duty feeders that can be used in the most difficult conditions for primary crushers, material feeding It is not the first time that I have been able The undercarriage, which is also used in crawler machines, is driven by a low-speed planetary gearbox or a parallel shaft or chuck gearbox. The drive shaft is connected from the double-sided drive gear center. With the rotation of the drive sprocket, it moves the pallet chains and therefore the pallets, and takes the material/ore on the Apron feeder. The pallet is hard to wear because it is cast with high manganese. Therefore, they are used in the most difficult conditions Crawler feeders are feeders used in primary hoppers when the crushed material becomes sticky with the effect of moisture as a result of containing soil or clay. Thanks to its strong structure and pallet system, it prevents feeding problems no matter how dirty and sticky the fed material is. For this reason, it is preferred in high-capacity (400 TPH and above) facilities.

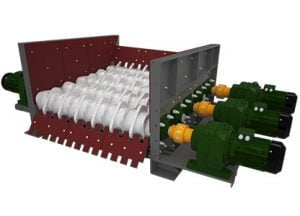

Wobbler Feeders Wobbler feedersare the feeder used to ensure the clean and regular flow of the raw material to the crusher before the primary crushing process in case the material to be crushed is excessively moist, sticky, wet and soily. The raw material, which works synchronously with each other and moves on eccentric shafts and elliptical parts, is separated from the earthy material adhered to its surface by the effect of both rotation and falling, and proceeds more cleanly and regularly.

Belt Feeders They are conveyor belt feeders used under intermediate product bunkers. The rotation of the belt tire is provided by a low-speed high-torque reducer that turns the drum. The reducer speed, again, can be changed with the help of frequency converter. A needle or linear cover flap should be placed between the feeder and the bunker in order to reduce possible tears in the belt feeder or to reduce the load on it. The feeding capacity depends on the width and speed of the feeder. They are used with machines where regular feeding is essential, such as cone crusher and vertical shaft crusher.  You can visit our Feeders Page to get detailed information about all our feeders and to request a quote.

You can visit our Feeders Page to get detailed information about all our feeders and to request a quote.