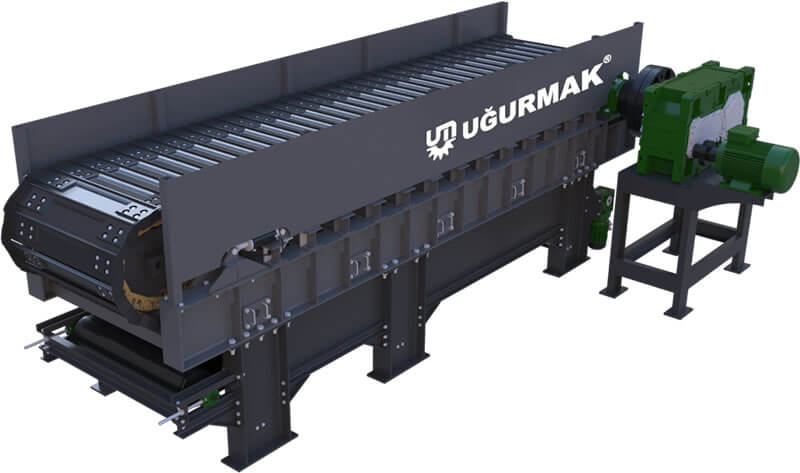

Apron feeders can operate horizontally or at an incline. In general, an Apron Feeder consists of overlapping abrasion-resistant pallets that are fastened on the chain with bolts, working like a conveyor. These chains, to which the pallets are attached, are driven by chain gears located on both sides.

Higher inclination further ensures building compact facilities, reducing the length of the feeder, and keeping investment costs low.

Apron feeders are a reliable solution for effectively feeding wet, sticky, dry or abrasive ores and materials of different sizes and densities.

Apron feeder’s diversity can be found throughout the mineral processing circuit fitting different applications with robust designs and high uptime for a more efficient operation. Apron feeders are built for reliability and performance in every task needed in mining. Thanks to its robust design, our Apron Feeders are a truly economical and reliable method of material handling to increase uptime and overall efficiency. Apron Feeders are manufactured in special sizes according to our customer’s request.

All of the pallets of UGURMAK UPB series Apron Feeders are produced from abrasion-resistant casting. The design of their pallets allows even sticky material to move rapidly. Worn-out pallets are fixed with bolts and their disassembly and assembly can be completed in a very short time. Cast alloy can be specially designed for the customer based on the abrasive properties of the fragile material.