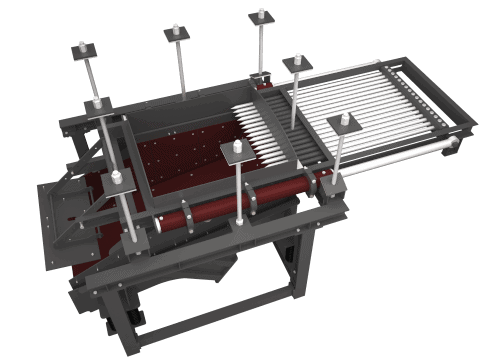

In some crushing and screening processes, there may be a need to divide the process in half. In such cases, tunnel type intermediate stock center is frequently preferred. It is positioned in the middle of the stock center. Their main field of use is to ensure that the stocked material is fed to the second stage of the process. This vibrating feeder type UTF series Tunnel Feeder provides high performance in heavy conditions.

These types of feeders can be produced as steel frame type fixed on the ground and hanger type fixed on the ceiling according to the customer preferences.

In order to control the flow of the material, a pin gate is used at the entrance of the tunnel. These pins can be controlled mechanically as well as hydraulically. In addition, there is a mechanical cover in the feeder input to control the flow of the material.