Impact crushers are indispensable machines for stone crushing and grinding operations. However, like any machine, impact crushers can wear out and malfunction over time. Having the right spare parts is crucial for the continuous and efficient operation of such machines. Having spare parts on hand prevents sudden breakdowns, reduces maintenance times, and prevents production losses.

Here are the top 5 must-have spare parts for impact crushers:

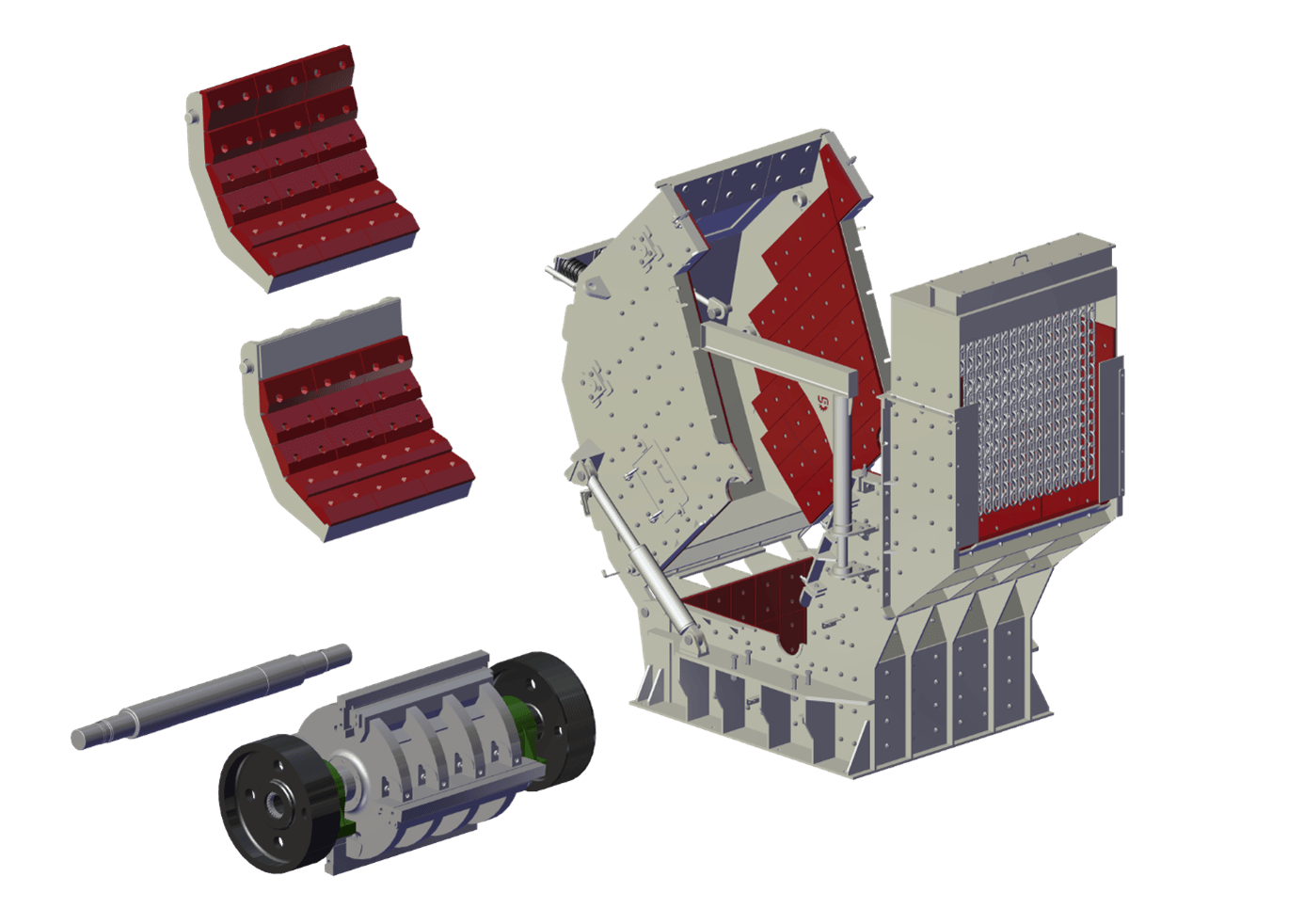

1. Impact Crusher Rotor: The Heart of Crushing Machines

The operating principle of impact crushers is that the rotors crush the stone by striking it while rotating rapidly. Therefore, rotors are one of the most critical parts of crushers. Over time, rotors can become damaged due to wear, impact, or intensive use. Having spare rotors is crucial for ensuring the efficient operation of your machines. Rotors made of high-quality alloy materials increase durability and maintain high performance.

Why Should You Have an Impact Crusher Rotor?

• It plays a critical role in crusher efficiency.

• Wear and deformation can occur during long-term use.

• It is crucial for ensuring production continuity. A spare rotor ensures production continuity in emergency situations.

2. Hammers: The Foundation of Crushing Power

Impact crusher hammers rapidly strike and break rocks. Hammers are manufactured from high-quality steel or alloy materials resistant to impact forces. Because these parts wear or break over time, it is crucial to have spare parts. Especially in high-intensity and demanding crushing operations, the durability of hammers directly affects performance.

Why Should We Keep Hammers?

• Because they are subject to high impact forces, these parts can wear quickly and severely.

• Poor-quality hammers reduce crusher efficiency.

• Spare hammers prevent malfunctions and operational disruptions, contributing to the continuity of the production process.

3. Wear Liners: Protecting the Internal Structure of Crushers

The abrasive surfaces inside impact crushers are the parts of the crusher that come into direct contact with the crushing stones. These surfaces, where the stones strike, can wear down and lose their function over time. Therefore, it is important to have spare abrasive surfaces. Surfaces made of durable materials extend the life of crushers and increase efficiency. They are generally manufactured using steel or high-alloy metals.

Why Should We Have Abrasive Surfaces?

• Wear occurs rapidly on surfaces where stones impact at high speeds.

• Protecting the internal structure of the machine ensures long-term operation.

• Spare abrasive surfaces prevent excessive wear.

4. Impact Crusher Outlet Throat: Increasing the Efficiency of the Removal Process

The outlet throat is the part of the impact crusher that allows the stones to be expelled after the crushing process. This part ensures the rapid removal of stones and, if worn, negatively impacts the crusher’s performance. A spare outlet throat is critical, especially for machines operating under heavy loads.

Why Should We Keep This Spare Part?

• It plays a critical role in crushers’ ability to extract stones.

• It can wear out over time due to exposure to high impact forces.

• A spare outlet throat prevents production interruptions.

5. Wheel and Shaft Connections: Vital Parts for Mobile Crushers

In mobile versions of impact crushers, the connection elements between the wheels and shafts are extremely important. These elements enable the crushers to move and efficiently crush the stone. Over time, these connection elements can wear out or break. Therefore, a spare set of wheels and connection elements should always be kept.

Why Should We Keep Connection Elements?

• They provide essential mobility for mobile crushers.

• Connections used at high frequencies can become damaged over time.

• Spare connection elements ensure machine mobility and continuity of production.

Impact crushers are critical to stone crushing and grinding operations. Having the right spare parts for the proper operation of these machines provides significant long-term cost savings and increases operational efficiency. The five main spare parts listed above are critical factors that directly affect the performance and lifespan of impact crushers. At Uğur Makina, you can source the highest quality spare parts for impact crushers. For detailed information and products visit our website: www.ugurcrushers.com