UĞURMAK brand Mechanical Stabilization Plant is used in the preparation of all kinds of mechanical materials used in road construction and airport runway construction. This mechanical material is obtained by mixing aggregate and sand of suitable size in the mechanical stabilization plant with a sufficient amount of water.

Before applying asphalt, it is necessary to increase the bearing strength of the existing ground and eliminate the internal stresses, if any, against problems such as collapse orpitting. To achieve this, only mechanical material can be laid on the existing floor before asphalt application.

This base layer, which will be laid before asphalt, must be suitable for compacting. Considering the 15-day sieve analysis results, the mixing ratios are determined according to the previous percentage rates. Foreign materials such as clay and silt should not be present in the mechanical material layer. Robust, clean aggregate should be used.

This will not only reinforce but also eliminate pits and even roughness on the ground. Asphalt material will not be used to fill these pits and savings will be achieved. Therefore, it will provide great benefit in terms of total cost.

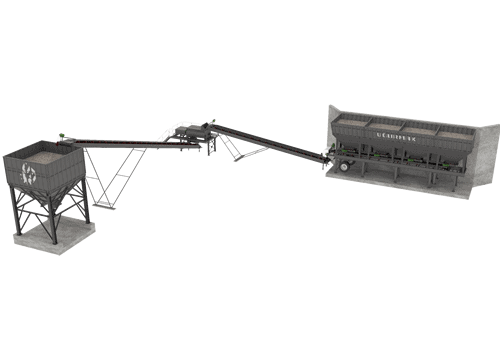

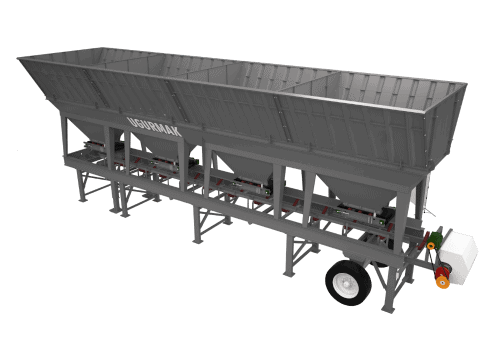

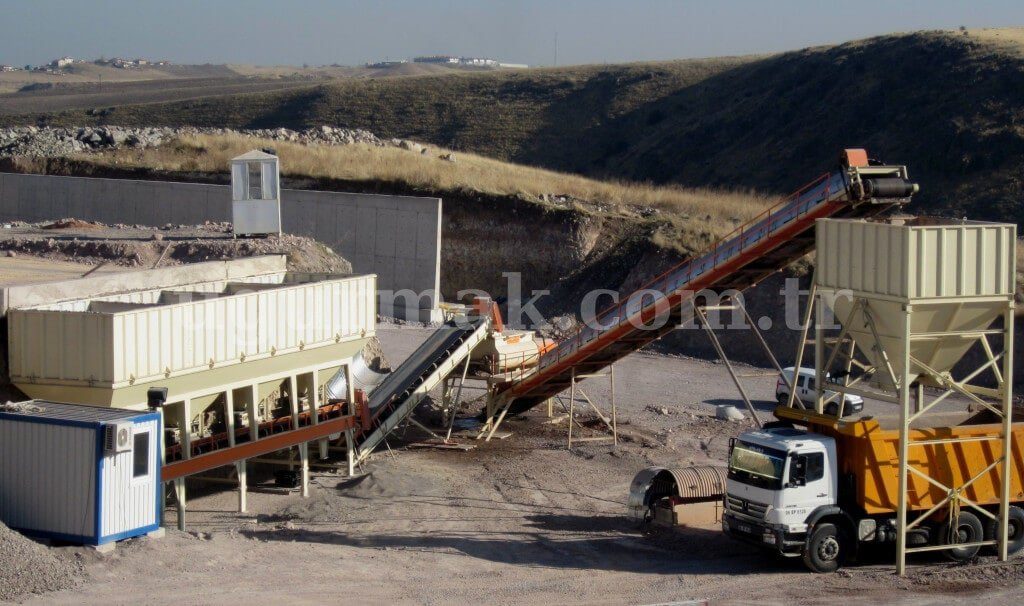

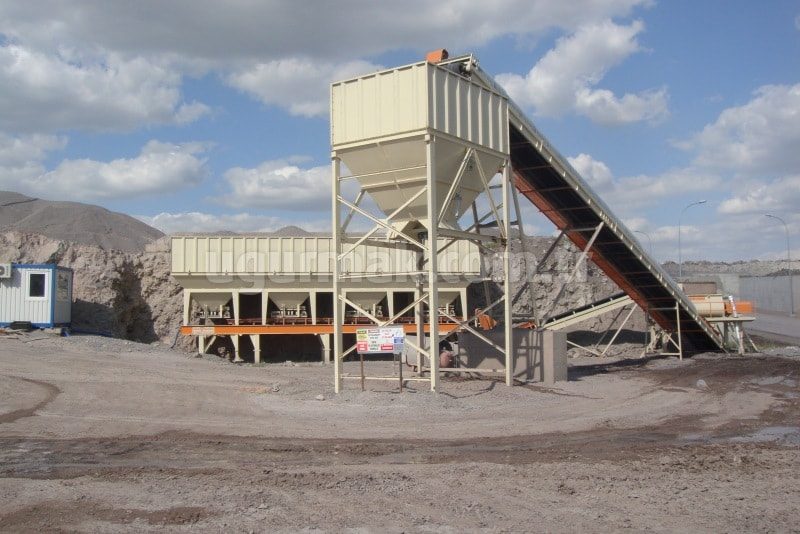

Aggregate Bunker

Cold aggregate bunkers have four units. Dosing belts are positioned at the discharge chutes of these bunkers. Dosing belts transfer the material to the collection belt, which is also in the same unit. Four different sizes of material are combined in a certain proportion of the collection tape. This material is carried from the collection belt to the mixer feeding belt and then to the mixer.

Mixer

The continious twinshaft mixer is covered with wear-resistant replaceable liners. Mixer arms made of cast steel are bolted on the shafts. Arms are designed to reach all the volume in the mixer. There are nozzles that will form a water jet at the exit points of the mixer so that the water can reach every point of the material.

Stock Bunker

The material mixed in the mixer reaches the Stock bunker with the belt conveyor. The stock bunker with pneumatically controlled chutes discharges the material directly into the truck underneath.