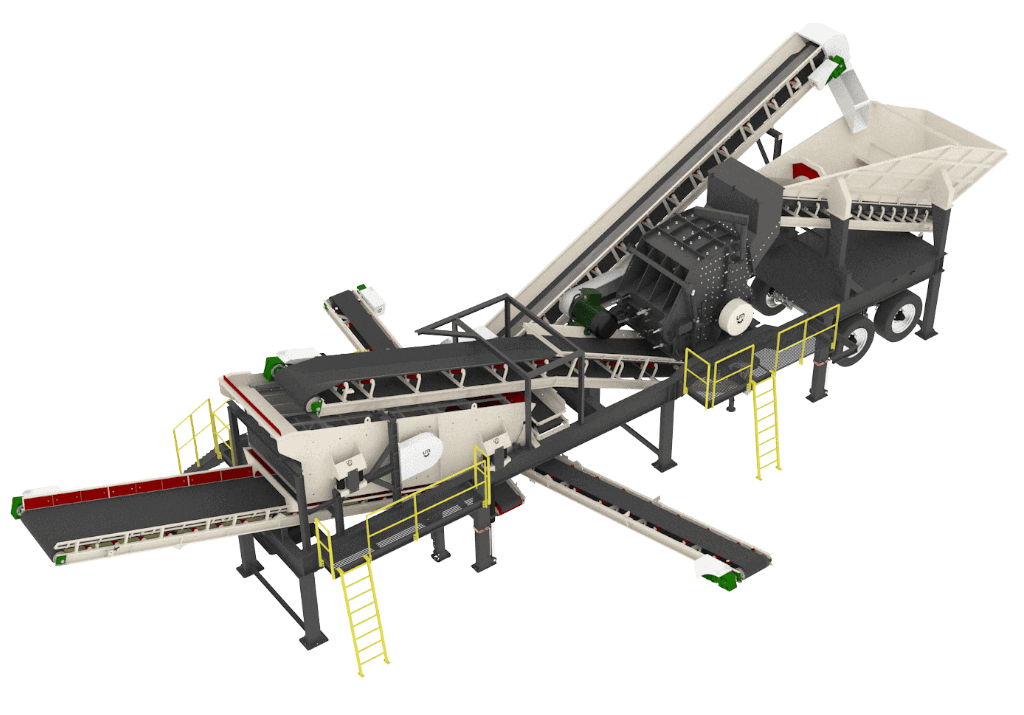

Temporary quarries established in project works such as dam and road construction may need to be moved to a different site at the end of the project. This has led to the need to develop portable facility concepts. Mobile groups can be transported more easily than stationary plants, significantly reducing transportation costs. In addition, it provides a serious advantage in fulfilling project commitments in a short time thanks to its fast transportation convenience.

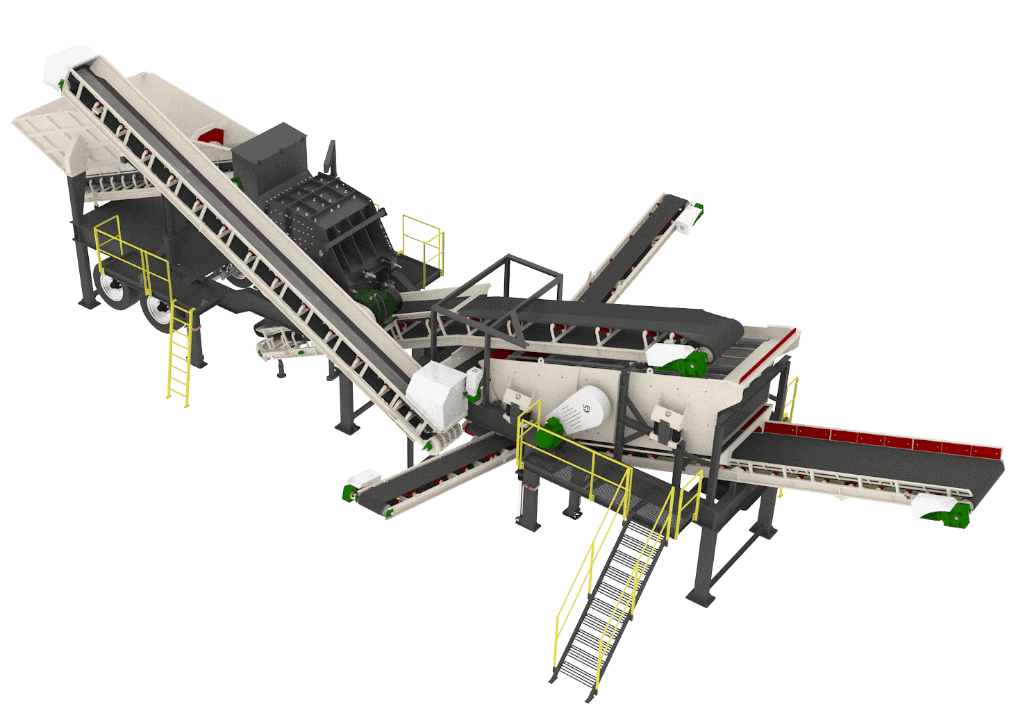

As UĞURMAK, we can meet the various needs of our customers with wheeled semi-mobile and tracked mobile group options. The crushers and screens we manufacture can be used on fixed chassis as well as adapted to mobile chassis to the extent permitted by road standards. UGURMAK mobile groups are designed to fully meet the needs of our customers with compact solutions such as hydraulic legs, foldable conveyor and bunker hopper options that provide the advantage of shorter and easier installation. We have mobile crushers, mobile screens or closed circuit mobile crushing and screening group designs that perform both crushing and screening operations on the same mobile chassis, which are required for an efficient plant design.

- The aggregate fed in our mobile secondary crushing and screening unit has a maximum size of +450 mm.

- The rotor speed can be adjusted according to the material crushing ratio. The jaw adjustment system is hydraulic, which provides convenience

- Due to their compact design, they take up less space than fixed solutions, making them more suitable for users who have to work in confined spaces. Since hydraulic legs are used, it provides the advantage of installation and disassembly.

- Generators can be added to mobile crushers according to customer request, providing advantages in transformer and cable costs.

- Mobile crushers are installed close to the stone to be crushed and provide advantage in the transportation of material to be fed from the mine.