Mining is a complex process that involves several stages that begin with drilling and blasting and culminate in the production of valuable aggregates. These aggregates are essential components in construction, infrastructure development, and many other industries. In this blog post, join us as we delve deeper into the world of drilling and blasting, exploring its importance, the subtleties involved, and the awe-inspiring power it wields. 1. Fundamentals of Drilling and Blasting : Drilling and blasting serve as the first steps in a variety of projects involving rock excavation, whether it is the creation of tunnels, the extraction of minerals, or the construction of foundations. Drilling is the basis of the process, which involves drilling holes in the rock face to facilitate controlled blasting. Modern drilling techniques use advanced machinery, such as rotary drills and hydraulic systems, which provide precision and efficiency. 2. Precise Planning: The Key to Success: A successful drilling and blasting operation relies on thorough planning. Geological surveys, rock analyses, and structural assessments contribute to the development of a comprehensive blasting plan. Factors such as rock type, density, and durability, as well as environmental concerns, should be carefully considered to determine the most appropriate drilling patterns, hole depths, and spacing. The use of computer-aided design (CAD) and simulation software helps to visualize the blast design and predict the effects on the surrounding environment. 3. The Art of Controlled Bloss: Controlled blasting, the explosive core of the process, allows for efficient rock fragmentation while minimizing the potential for damage. A series of explosives such as dynamite and ANFO (Ammonium Nitrate/Fuel Qil) are used according to the desired explosion result and rock properties. Sequential starting, in which the holes are blasted in a specific order, creates a controlled release of energy, preventing excessive vibration and minimizing the risk of flying.

Mining is a complex process that involves several stages that begin with drilling and blasting and culminate in the production of valuable aggregates. These aggregates are essential components in construction, infrastructure development, and many other industries. In this blog post, join us as we delve deeper into the world of drilling and blasting, exploring its importance, the subtleties involved, and the awe-inspiring power it wields. 1. Fundamentals of Drilling and Blasting : Drilling and blasting serve as the first steps in a variety of projects involving rock excavation, whether it is the creation of tunnels, the extraction of minerals, or the construction of foundations. Drilling is the basis of the process, which involves drilling holes in the rock face to facilitate controlled blasting. Modern drilling techniques use advanced machinery, such as rotary drills and hydraulic systems, which provide precision and efficiency. 2. Precise Planning: The Key to Success: A successful drilling and blasting operation relies on thorough planning. Geological surveys, rock analyses, and structural assessments contribute to the development of a comprehensive blasting plan. Factors such as rock type, density, and durability, as well as environmental concerns, should be carefully considered to determine the most appropriate drilling patterns, hole depths, and spacing. The use of computer-aided design (CAD) and simulation software helps to visualize the blast design and predict the effects on the surrounding environment. 3. The Art of Controlled Bloss: Controlled blasting, the explosive core of the process, allows for efficient rock fragmentation while minimizing the potential for damage. A series of explosives such as dynamite and ANFO (Ammonium Nitrate/Fuel Qil) are used according to the desired explosion result and rock properties. Sequential starting, in which the holes are blasted in a specific order, creates a controlled release of energy, preventing excessive vibration and minimizing the risk of flying.  4.Safety Measures: Protecting Both People and the Environment: Safety is paramount in the field of drilling and blasting. Strict safety protocols, training and protective equipment ensure the safety of the employees involved. Measures such as pre-blast inspections, vibration monitoring, and dust control systems are implemented to reduce environmental impact, which help protect surrounding ecosystems, prevent air pollution, and maintain an approach. 5. Future Shaping Developments: As technology advances, so does the field of drilling and blasting, Innovations such as laser-guided drilling, GPS-enabled precision blasting, and remote-controlled systems improve accuracy, reduce human error, and increase productivity. Additionally, the integration of AI-powered algorithms and real-time data analysis enables smarter decision-making, optimizing the process and minimizing costs.

4.Safety Measures: Protecting Both People and the Environment: Safety is paramount in the field of drilling and blasting. Strict safety protocols, training and protective equipment ensure the safety of the employees involved. Measures such as pre-blast inspections, vibration monitoring, and dust control systems are implemented to reduce environmental impact, which help protect surrounding ecosystems, prevent air pollution, and maintain an approach. 5. Future Shaping Developments: As technology advances, so does the field of drilling and blasting, Innovations such as laser-guided drilling, GPS-enabled precision blasting, and remote-controlled systems improve accuracy, reduce human error, and increase productivity. Additionally, the integration of AI-powered algorithms and real-time data analysis enables smarter decision-making, optimizing the process and minimizing costs.  Conclusion: The art of drilling and blasting represents the intersection of engineering expertise and raw power. From careful selection of drilling sites to controlled release of explosive energy, this process allows us to uncover vast resources, drill intricate tunnels, and build awe-inspiring structures. As the industry continues to evolve, the future promises even greater precision, safety, and sustainability in drilling and blasting. Acknowledging its role in shaping the world we live in, let’s marvel at the creativity behind this essential technique.

Conclusion: The art of drilling and blasting represents the intersection of engineering expertise and raw power. From careful selection of drilling sites to controlled release of explosive energy, this process allows us to uncover vast resources, drill intricate tunnels, and build awe-inspiring structures. As the industry continues to evolve, the future promises even greater precision, safety, and sustainability in drilling and blasting. Acknowledging its role in shaping the world we live in, let’s marvel at the creativity behind this essential technique.

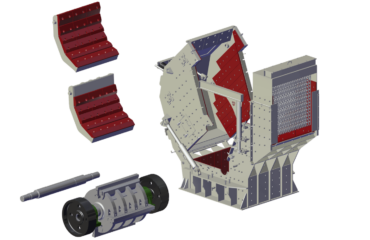

Uğurmak is a leading manufacturer specializing in crushing, screening, and washing plants for the mining, construction, and recycling industries. The company offers a wide range of high-performance machines, including jaw crushers, impact crushers, cone crushers, vibrating screens, and washing systems, designed to process a variety of materials such as rock, ore, and construction waste. Uğurmak’s products are built to meet the demands of heavy-duty applications, providing efficiency, durability, and ease of operation.

Copyright © 2024, All Rights Reserved.