The Importance of Crushing, Screening, Washing Plants

The Importance of Crushing, Screening, Washing Plants

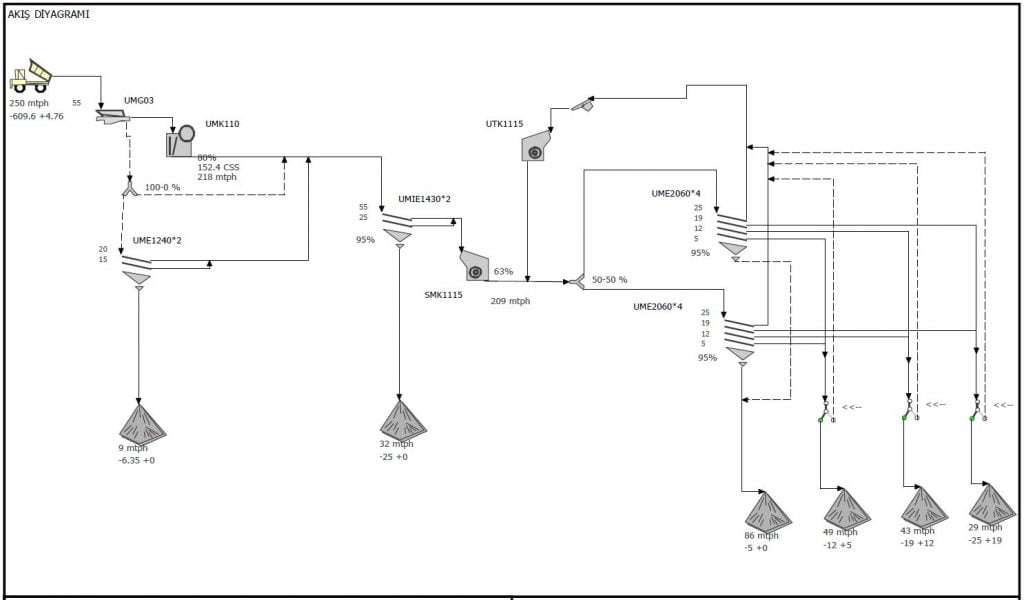

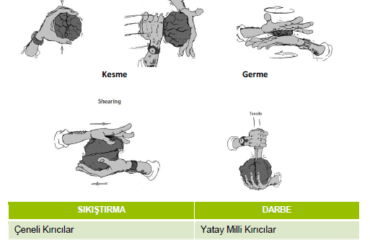

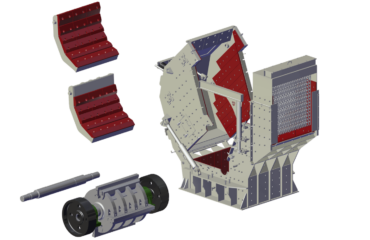

In our country, with the growth of industry and the advancement of urbanization, the development of construction activities (concrete, cement, asphalt, ballast, etc.) and the increase in the need for mining raw materials have gained importance in the use of Crushing-Screening Plants and related equipment. Crushing and Screening Plants are electro-mechanical facilities used for the production of crushed stone (concrete, cement, asphalt, ballast, etc.) in the construction sector and for the processing of ore produced in the mining sector. In order to keep the quality and cost of the material produced in these facilities in balance, experience and knowledge are required in the production of the facility. Uğur Makina produces quality, efficient and suitable facilities as a result of the cooperation and harmony of different professional groups (machinery, mining, geology, construction, electrical-electronics, software, business, economics, sales, foreign trade, etc.) who are experts in their fields. In order for the crushing and screening plants to be efficient and of high quality as well as to fully meet the demands of the customer, they should be designed by experienced people in the field, and the geological and structural properties of the material to be crushed should be examined and taken into account in the selection of machinery and equipment. After the designed facility is designed in detail and produced by experts, field assembly should be done. The material, which is extracted from quarries or streams by drilling-blasting and/or direct backhoe loaders and brought to the facility, is generally subjected to three different crushing processes. As a result of these crushing processes, which are called primary, secondary and tertiary, the material is classified in the desired dimensions by passing through sieves, if the material needs to be washed, it is washed and the last stage of crushed stone (aggregate) production is completed. The product obtained is sent to asphalt plants for road construction and to concrete plants for reinforced concrete structures. In the mining sector, the crushing and screening plant is the first stage of size reduction. The ore extracted from the mine is brought to the facility by drilling-blasting and/or direct backhoe loaders; It is subjected to three different crushing processes in accordance with the process form. The ore, which is reduced in size by sifting through suitable sieves, is sent to the grinding circuit after the crushing cycle, if deemed necessary according to the appropriate process.