Vertical shaft impact crushers are used in mining, construction, aggregate, concrete, asphalt, stone and sand quarry sectors; It is generally used as a tertiary after primary or secondary crushers to obtain thin and cubic material by crushing materials.

It is preferred in the crushing circuits of materials such as limestone, stream material, basalt, granite, andesite and dolomite.

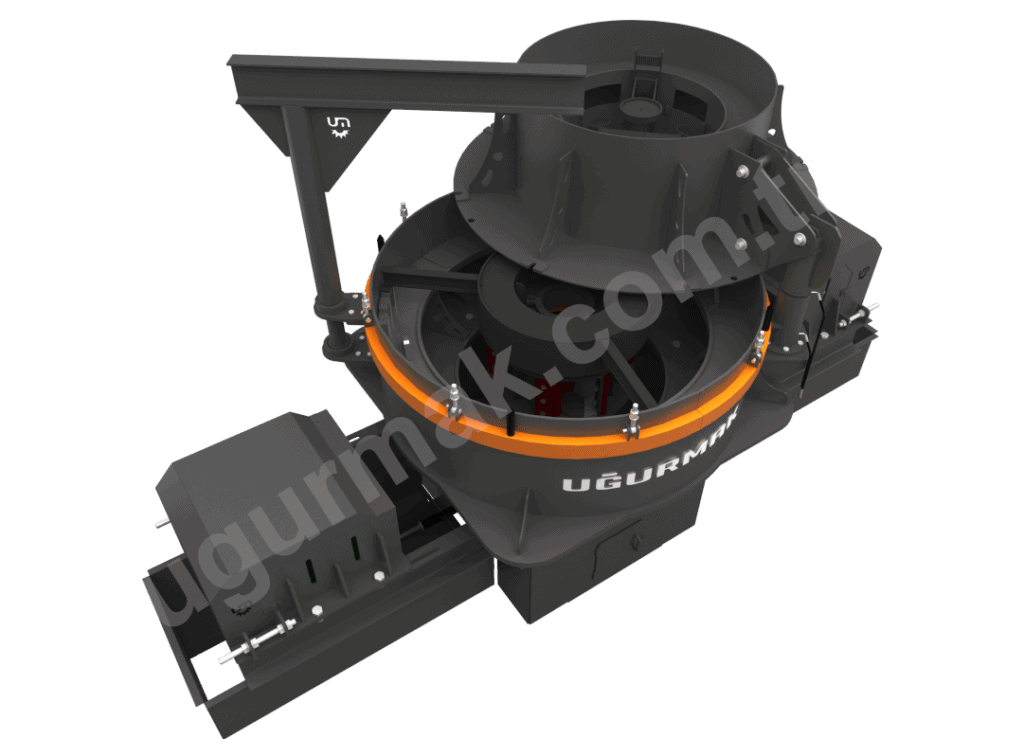

Vertical shaft impact crushers, consisting of a dispersing rotor and a crushing chamber, instead of reducing the size by compressing the material between two plates, unlike other crusher types; It accelerates the materials thanks to the high-speed distributor rotor and hits the stone and the crusher wall.

It is produced in two different ways: closed rotor and open rotor.

The inner surface of the closed rotor vertical shaft crusher rotor is covered with cast liner. At the outlet, there are diamonds that are resistant to abrasion and can be easily replaced. By breaking the stone by hitting the stone, a longer working life and high efficiency are achieved, as well as the cost per ton and the cost of spare parts are low. In addition, a drier product is obtained by reducing the water in the crushed material.

In open rotor vertical shaft crushers, there is a rotor with an open top and an anvil set fixed at a certain angle and distance around this rotor and covered with steel cast liners. The material entering the crusher through the feeding tube falls on the distributor liner in the center of the rotor and reaches the crusher pallets. The pallets accelerate the material and break it by hitting the anvile, and the materials fall into the discharge chute.

The operation of the vertical shaft crusher is limited by the feed size and material properties. While a maximum of 40 mm of material is fed to closed rotor crushers, the maximum feed size can be increased to 100 mm in open rotor crushers.

Since there is no adjustable mouth opening in vertical shaft impact crushers, the product size fineness adjustment is made in a controlled manner by changing the rotor speed. When the rotor is accelerated, more thin material is produced, and when it is slowed down, less thin material is produced.

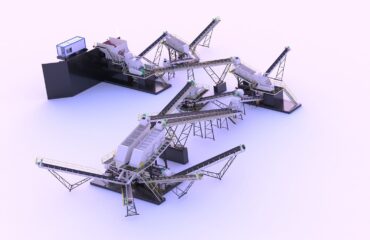

Vertical shaft crushers, which can produce cubic shaped products, are easy to use, assemble and maintain thanks to their modular design, with high size reduction, thin and homogeneous product ratio, and low cost and operating costs. It continues to work smoothly and efficiently with its automatic lubrication system. According to the needs of the facility, it is designed to be mobile, fixed steel leg or fixed slide chassis.