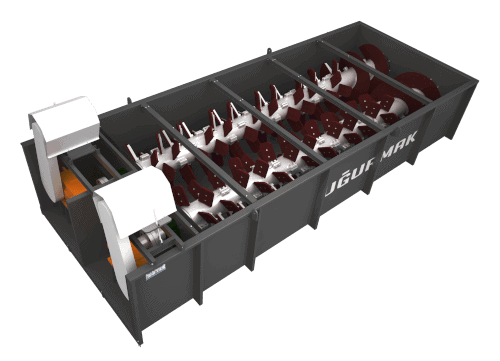

UĞURMAK UPY Series blade mills are generally used in the washing process when they need to be processed before washing at screens to increase screening efficiency or before other washing equipment such as vibrating washing screen, sand classifier or dewatering screen. It is used to purify the stone from soil, clay and other unwanted particles.

They are produced with double shafts. On the shaft, there are detachable fixed spiral leaves and washing shovels lined up with the most suitable combination. It is very easy to replace shovels and spiral leaves since they are detachable connected. These shafts are driven by motor, reducer and belt pulley system.

With the design of the paddles and leaves that are optimally arranged along the shaft, the material is pushed towards the center and the undesired particles on the material that rub each other are abraded and cleaned by this decomposition effect.

It looks like sand classifiers. However, there is no water reservoir in the feeding part like the washing spiral. Therefore, the material and the water are together fed to outlet chute. In addition, both fine and coarse material can be fed, but they cannot separate hard clay. Moreover, as already mentioned, after blade mill, another washing equipment must be used.