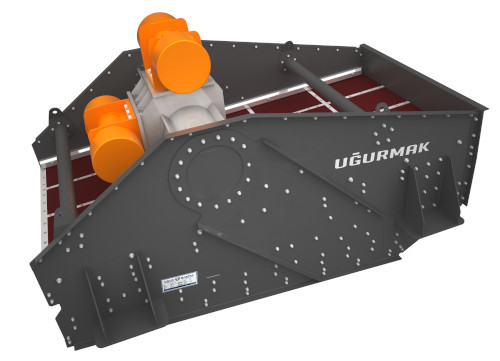

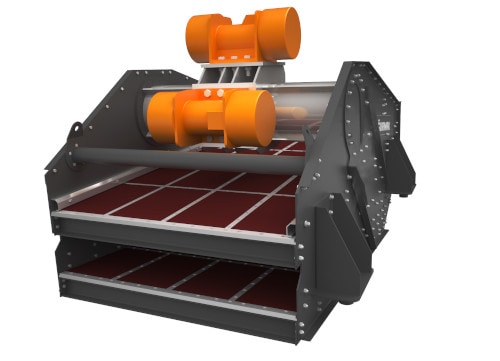

UĞURMAK UMDS series dewatering screens are designed to remove water from the sand that has been reclaimed in a washing system. After any washing process, the sand contains a minimum of 20% water. It may be possible to store this amount of water in bulk and filter it after weeks. However, this increases the stock cost excessively. For this reason, dewatering screens are very valuable equipment for washing systems.

• It quickly removes the water contained in the sand.

• A product with a very low level of moisture is obtained.

Washed sand is fed to the inclined screen surface in the feeding section of the UMDS series dewatering screen. The screen frame is designed to slope upwards. While the material climbs this upward slope thanks to the linear movement created by the vibromotors, water cannot climb and forms a pool in the intersection of the feeding and climbing movement. Therefore, liquid and very small organic fibers are separated from the sand through the meshes of the polyurethane screen wires with very small mesh spaces that serve as filters and are forced to be discharged from the screen. The water taken is recycled in the system for reuse. The sand is obtained as dewatered.