What Are the Rocks Used as Aggregate in the Crushing and Screening Plant?

The rocks used in the production of crushed stone (aggregate) in the world and in our country are generally limestone, dolomite, basalt, andesite, granite and river material etc. Due to the different geological and structural features of the rocks, the equipment to be used in the plants varies.

Machine and equipment selection is made according to the properties of rocks in Mohs hardness scale, Los Angeles values, brittleness, compressive strength, chemical analysis, etc. Crusher parts and accessories with the same characteristics should not be used for different rock types such as limestone, sandstone, granite, basalt. The castings of the crusher produced for limestone and the castings and parts of the crusher produced for basalt are different. Uğur Makina develops suitable components according to the characteristics of the rock and works to minimize the operating costs of the crushing and screening plants it undertakes. As examples, details for limestone and basalt from rocks are explained below.

Limestone ;

Limestone

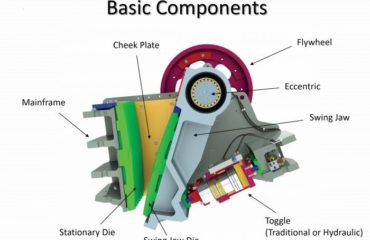

It is included in the sedimentary rock group. Limestone, the raw material of lime, is usually composed of calcium carbonate (CaCO3). It is usually white in color. Mohs hardness value is around 3- 3.5. After the XRF analysis of the material, it can be called dolomite according to its Mg content. Sedimentary rocks can be formed by the fragmentation, transportation, accumulation and petrification of previously formed rocks, as well as from organisms that lived in the past. This rock group generally has a layered structure. In limestone plants, primary jaw or impact crushers, secondary impact crushers, tertiary impact crushers and vertical shaft crushers are generally selected and plants suitable for demand are designed. Manganese alloy castings are generally used in crusher parts (palette, lining, etc.).

Basalt;

bazalt

It is included in the group of volcanic surface rocks among igneous rocks. It is black in color and in dense piles. It is found in nature as mass, vein and flow. Mohs hardness value is around 5.5 – 6.5. Since it is an igneous rock, it contains a high amount of silicon. Therefore, its abrasiveness is quite high. For this reason, chrome alloy castings are preferred in crusher parts (palette, lining, etc.). In basalt plants, primary jaw crushers, secondary cone crushers and secondary jaw crushers, vertical shaft crushers are selected as tertiary crushers, and plants suitable for demand are designed. In addition, the flow surfaces of the material are covered with hardox lining due to the high abrasiveness in the entire plant.