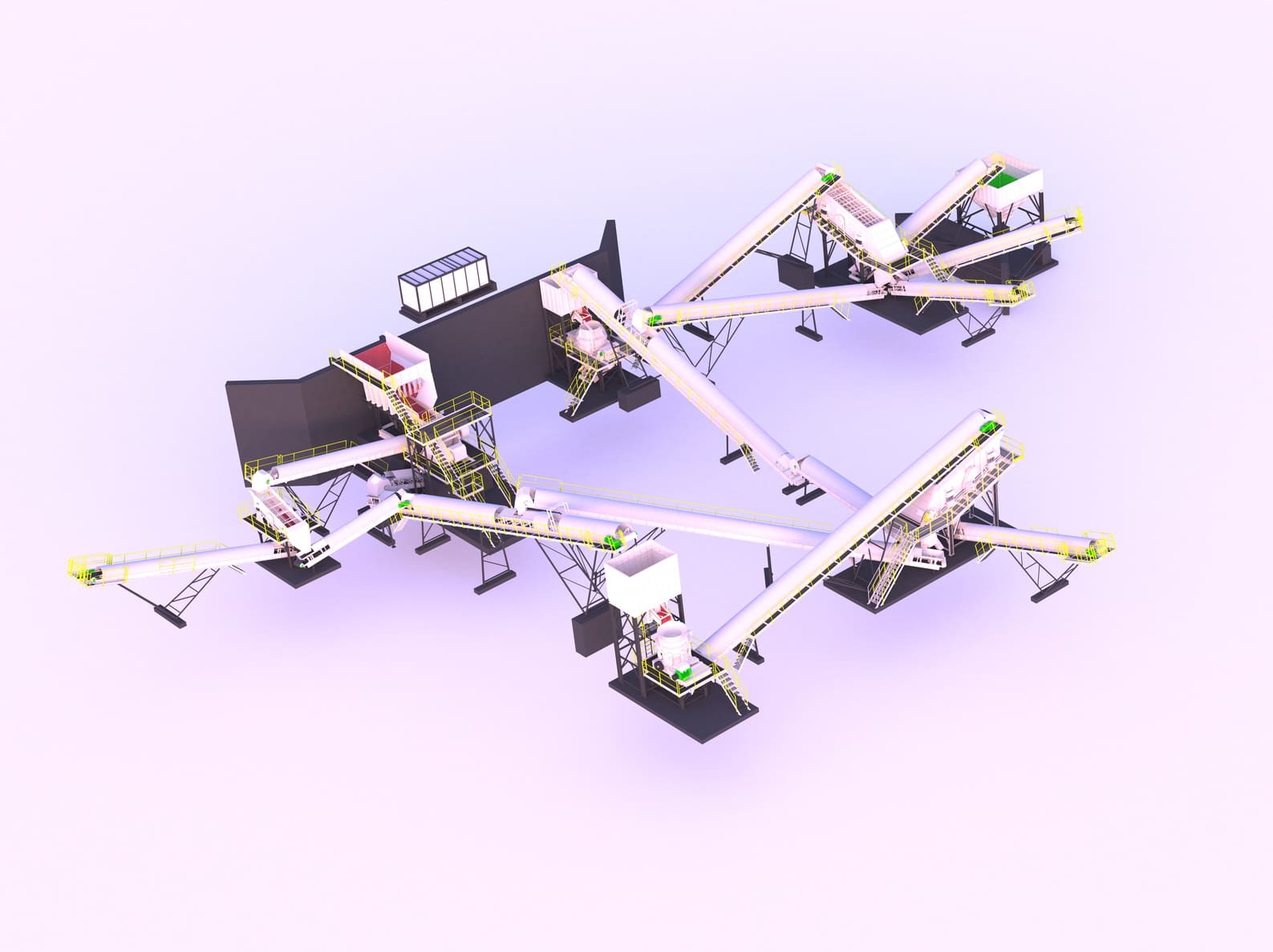

After the devastating earthquake in Turkey in 2023, we worked hard to contribute to the reconstruction of the destruction in the region by commissioning the fixed crushing and screening plant, which is one of the many facilities we established in the earthquake zone, in the fastest way possible. UMK series 110 jaw crusher was used as the primary crusher in the facility. The fed material is basalt, which is very hard, and jaw crushers, which break the stones by applying high pressure, show very little wear compared to impact crushers in abrasive mines due to the crushing principle and jaw surfaces, which provides an effective advantage in cost. It provides simple maintenance and operational convenience in continuously operating facilities. These crushers, which consume less energy, provide the most ideal crushing solution especially for shrinking large stones.

Vertical shaft crusher UDK900 from our UDK series was used as a tertiary crusher in the facility. Vertical shaft crushers are based on the principle of impact crushing thanks to their fast-rotating rotor; It is an ideal crusher type to obtain fine-grained, cubic-shaped material, and is ideal in the production of aggregates, especially needed in concrete and asphalt production. Again, with its extremely high performance in reducing and thinning hard stones, it is aimed to obtain high quality thin materials in hard stones such as basalt.

As a secondary crusher, cone crushers give ideal results in thinning the materials coming out of the jaw and ensuring homogeneity in dimensions, thanks to cone crushers, which are generally preferred as secondary and tertiary crushers. It is good material in construction and asphalt aggregate and has been used in the plant for its efficient crushing and operational advantages.

In the facility, the final product works smoothly with dimensions of 5,12,22 cm and a capacity of 300 tons per hour and serves the aggregate needs of the region.

In addition, UME series 2060 3-layer and 2060 4-layer screen were used to separate the crushed material in the facility. UME series inclined screens, with their weldless body design, have a more reliable body structure against the negative effects of vibration movement. In addition, the front groove has a rail system, so wire change can be done easily and quickly. The fact that the sieve body has platforms on all four sides provides safe and easy maintenance.

Machines used in the facility;

UMK110

UDK900

CONE CRUSHER

UME2060*3

UME2060*4

UME1240*2

UMG03

Type of Stone: Basalt

Capacity: 250-300 tph

Resulting Product: 5,12,22