Crushing and screening plants play a critical role in reducing large-sized materials obtained from quarries to the desired dimensions. Aggregates used in construction, concrete, and road building are processed through crushing and screening to achieve the target sizes. Plant design is among the key factors for efficiency and cost optimization. Here’s what you need to know about flow charts and proper plant design in crushing and screening facilities:

Efficiency and Importance of Crushing and Screening Plants

The selection and layout of equipment in crushing and screening plants directly affect the quality of the final product. The following factors are considered to enhance efficiency in these plants:

– Crushers: Primary, secondary, and tertiary crushers reduce the material to the desired size based on the rock dimensions.

– Screens and Conveyors: These are essential for classifying and transporting materials. Details such as conveyor height, slope, and motor speeds play a decisive role in efficiency.

– Feeding Capacity and Vibration Settings: Controlled material transfer is ensured through feeders.

– Geological and Chemical Properties of the Rock: Equipment selection is based on rock characteristics such as brittleness, abrasiveness, and moisture content during plant design.

What is a Flow Chart?

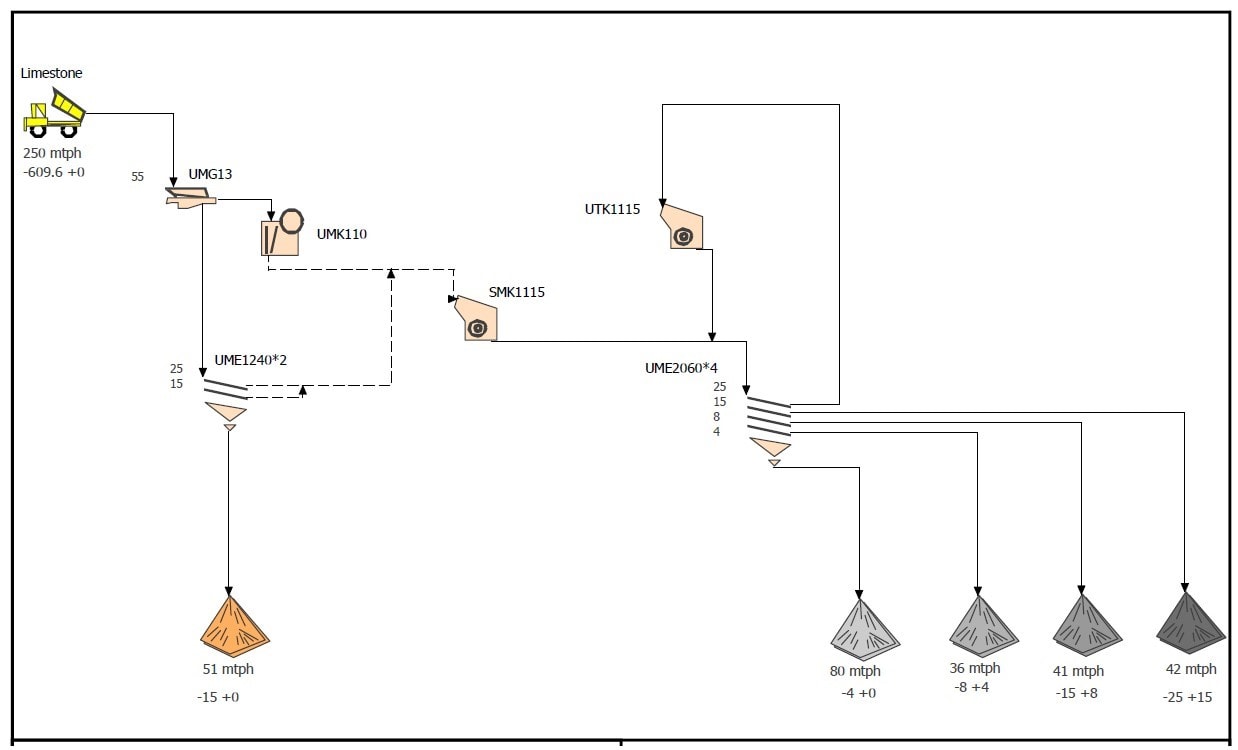

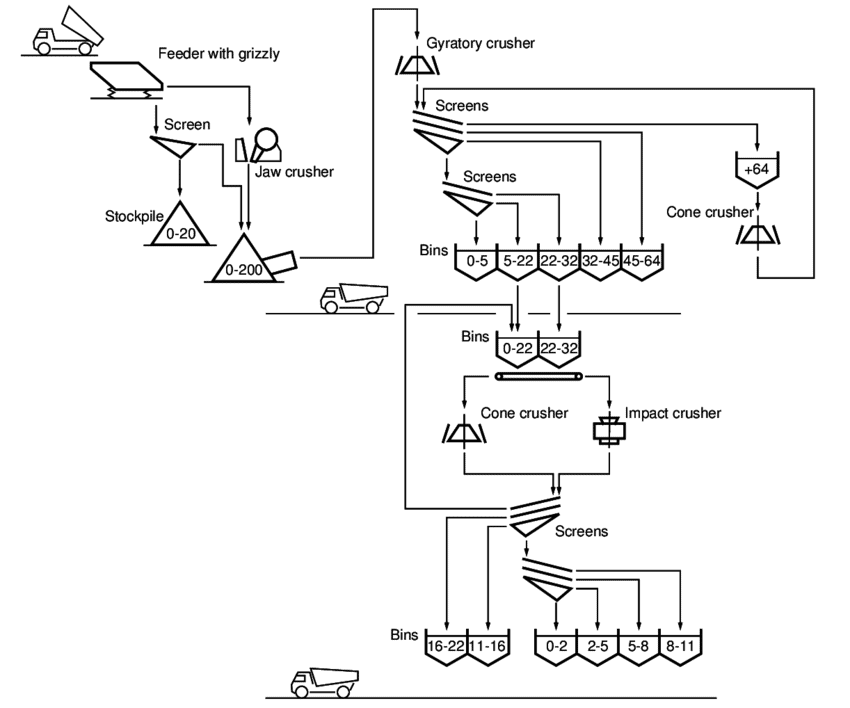

A flow chart is a diagram that shows the layout of equipment and the process flow in crushing and screening plants. This diagram ensures the plant is designed with the right equipment and improves efficiency.

Flow Chart and Plant Design:

When creating a flow chart, the following data is considered:

– Feeding capacity and material properties

– Particle size and brittleness level

– Abrasiveness and moisture content

Use of Simulation Programs:

Simulation is a technique used to enhance plant performance. Realistic models are created to optimize equipment layout and process flow. This helps:

– Prevent incorrect equipment selection.

– Minimize over- or under-capacity issues.

– Reduce production costs.

Plant Design with Uğur Makina

Uğur Makina offers customized plant designs by evaluating customer demands. The company follows these steps in designing crushing and screening plants:

1. Demand Analysis:

Customer needs and rock properties are assessed.

2. Flow Chart Creation:

Equipment layout and capacity calculations are made.

3. Appropriate Equipment Selection:

Machines such as feeders, crushers, and vibrating screens are selected based on technical specifications and material properties.

4. Layout Plan and Pricing:

A cost-effective design is created while planning the plant layout.

Advantages of Using Flow Charts in Plant Design

– Correct Equipment Selection: Prevents incorrect equipment choices.

– Increased Efficiency: Ensures the plant operates at higher performance levels.

– Cost Optimization: Eliminates over-capacity issues and reduces costs.

– Ease of Planning: Speeds up the production process with accurate planning.

Proper equipment selection and flow chart creation are among the most important steps to enhance efficiency and quality in crushing and screening plants. Uğur Makina, with its industry experience and innovative simulation programs, offers plant designs tailored to customer needs. This process not only reduces production costs but also creates a more efficient working system.