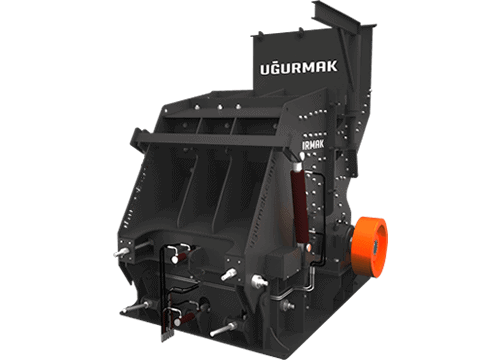

UĞURMAK IMPACT CRUSHER Impact crushersare suitable for materials containing parts weighing 100-5000 kg. The design of the feeding chute in these crushers allows the fed material to enter the machine tangentially to the crusher pallets. This design method is used in CDK and SMK type impact crushers, which are among the products of Uğur Makina.

The purpose of this is to ensure that the material is rotated and sent to the fixed crushing jaws. The speed supplied to the part is several times less than the rotor circumference speed. Thus, a high amount of force to the rotor bearings is prevented. After passing between the rotor and the fixed jaw, the crushed parts enter the narrower second and third crushing chambers. As a result, the material with a layered structure takes a cubic shape. The most important advantages of impact crushers are as follows;

The purpose of this is to ensure that the material is rotated and sent to the fixed crushing jaws. The speed supplied to the part is several times less than the rotor circumference speed. Thus, a high amount of force to the rotor bearings is prevented. After passing between the rotor and the fixed jaw, the crushed parts enter the narrower second and third crushing chambers. As a result, the material with a layered structure takes a cubic shape. The most important advantages of impact crushers are as follows;

- It provides a high size reduction ratio.

- Thanks to the closed design, dust generated during crushing is easily prevented by dust reduction solutions such as suction and water jet.

- Rotor balancing does not require high costs

- An important benefit for mineral enrichment is that the crushing force it exerts on the material is more oriented towards the periphery of the part. Thus, a quality segregation occurs during crushing.

- A high amount of fine material and a small amount of medium material are obtained with very little dust.

- Aerated material, which is soft on the outside and the inside, breaks especially easily.

The disadvantages of impact crushers include:

- Due to the rotor rotating at high speed, the crusher works like a fan and this airflow causes excessive dust formation.

- Adjusting the small part ratio is difficult in some designs. This is due to the fact that it is impossible in some designs to adjust the clearance between the rotating rotor and the crusher fixed jaws.

Uğur Makine has designed an adjustment mechanism to eliminate these disadvantages in its designs. In this way, the size reduction ratio can be easily adjusted.

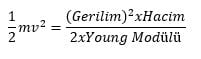

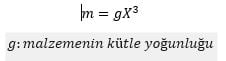

IMPACT CRUSHER MECHANISM If the impact is successful, the relationship between kinetic energy and tensile energy is as follows.  Equation – 1 where m and v are the mass and velocity of the material particle. The structure and design of the pallet should be such that it can absorb this tensile energy. If we examine it in terms of the material being fed:

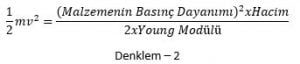

Equation – 1 where m and v are the mass and velocity of the material particle. The structure and design of the pallet should be such that it can absorb this tensile energy. If we examine it in terms of the material being fed:  Equation – 2 Assuming that the material is cubic and its size is “X”,

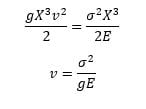

Equation – 2 Assuming that the material is cubic and its size is “X”,  Thus:

Thus:  This velocity value is 5 m/s for limestone. About 10 times this speed value is used for the rotor. According to JOISEL, the work done to break the part is equal to the force multiplied by the path taken by the part from the moment of impact to the moment of stopping. Force, on the other hand, is equal to the product of stress and area. Thus, the work done:

This velocity value is 5 m/s for limestone. About 10 times this speed value is used for the rotor. According to JOISEL, the work done to break the part is equal to the force multiplied by the path taken by the part from the moment of impact to the moment of stopping. Force, on the other hand, is equal to the product of stress and area. Thus, the work done: ![]() According to this equation, R is the ratio of Size Reduction. This work will be equal to the kinetic energy supplied to the part. Kinetic Energy:

According to this equation, R is the ratio of Size Reduction. This work will be equal to the kinetic energy supplied to the part. Kinetic Energy:  It happens. This value is found as 50 m/s, for example, for limestone. Hard materials require higher rotor speed than soft materials. The size reduction ratio can reach up to 40:1. Usually the numbers reached are 10:1 and 20:1. Click for Our Crusher Types and Technical Information

It happens. This value is found as 50 m/s, for example, for limestone. Hard materials require higher rotor speed than soft materials. The size reduction ratio can reach up to 40:1. Usually the numbers reached are 10:1 and 20:1. Click for Our Crusher Types and Technical Information