In aggregate production, reducing materials to the desired size is of great importance. The size reduction process involves crushing and grinding, which determine the quality of aggregates used in sectors such as construction, roads, and asphalt. So, what is size reduction, and what equipment and methods are used in this process?

What is Size Reduction? Differences Between Crushing and Grinding

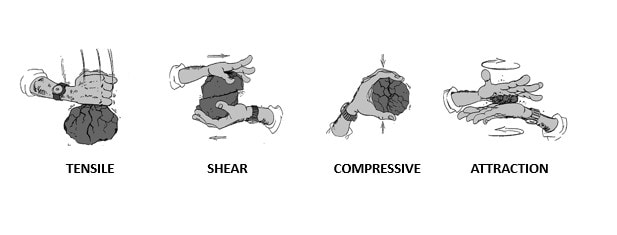

Size reduction is the process of breaking down materials into smaller pieces by applying force to particles. Two key terms stand out in this process:

– Crushing: This is the process carried out in crushers and is typically applied to run-of-mine ore.

– Grinding: This is the process performed in mills to achieve finer sizes and liberate mineral particles.

Size reduction can be done either dry or by mixing the material with water to form a pulp. The product obtained from crushing is coarser compared to that from grinding.

Stages of Size Reduction: Coarse Crushing, Fine Crushing, and Grinding

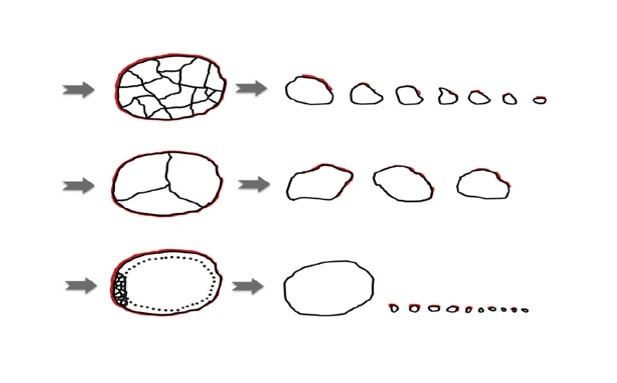

The size reduction process occurs in three main stages:

1. Coarse Crushing:

– Produces product sizes larger than 150 mm.

– This is usually the first stage where run-of-mine ore is initially crushed.

2. Fine Crushing:

– Produces product sizes between 150 mm and 10 mm.

– This stage involves more precise crushing to further reduce particle sizes.

3. Grinding:

– Reduces particle sizes to less than 10 mm.

– This is a critical process for liberating mineral particles and is commonly used in cement and filler material preparation.

Aggregate Preparation Process for Construction and Road Sectors

Size reduction plays a critical role in aggregate production. Crushing and grinding processes are carefully planned to ensure that aggregates used in construction and road sectors meet the required quality standards.

– Filler Material Production: Coarse and fine crushing processes prepare large pieces used in road fillings.

– Cement and Asphalt Production: Fine crushing and grinding stages are used in the preparation of raw materials for construction materials like cement and asphalt.

Proper size reduction ensures that materials are suitable for their intended use and enhances their processability.

Equipment and Techniques Used in Size Reduction

The efficiency of size reduction processes depends on the equipment and techniques used:

1. Crushers:

– Jaw crushers

– Cone crushers

– Impact crushers

2. Mills:

– Ball mills

– Rod mills

3. Screening and Classification:

– Screens and classifiers are used to separate products after the size reduction process.

Each piece of equipment is selected based on the material’s hardness, moisture content, and size. Proper selection ensures optimal performance and efficiency in aggregate production.