CRUSHING AND SCREENING PLANT

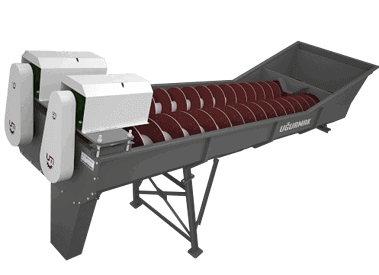

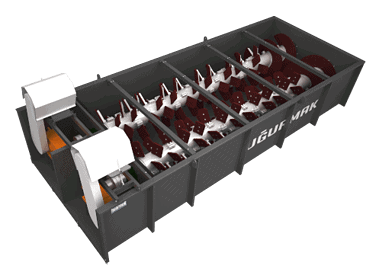

CLASSIFIERS - WASHERS

Classifiers are essential for achieving precise size control, ensuring that materials are sorted to meet specific requirements, which in turn leads to improved product quality and enhanced overall efficiency. By optimizing the separation process, classifiers help increase throughput and reduce waste, making operations more productive. These versatile systems can be applied across various industries, including mining, where they aid in sorting ores, and in the production of aggregates and manufactured sand, where they ensure the consistency of particle size.